Published July 2012

Revised January 2014

By B. Monrabal, J. Sancho-Tello, J. Montesinos, R. Tarín, A. Ortín, P. del Hierro, M. Bas. Polymer Char, Valencia, Spain.

Introduction

Gel Permeation Chromatography (GPC), also referred to as Size Exclusion Chromatography (SEC), when applied to polyolefin analysis (Polyethylene, PE and Polypropylene, PP) has been considered a demanding task due to the requirement of high-temperature operation and the use of hazardous chlorinated solvents for resin dissolution. In the last twenty years, the sample preparation process – of major importance in the GPC/SEC analysis of polyolefins – has not advanced significantly; vials are being filled with solvent manually and, in most cases, external filtration after dissolution is carried out with subsequent manual vial transfer before injection. Sample degradation, especially in the case of polypropylene, has not been completely eliminated and samples still remain at high temperature longer than required for proper dissolution.

GPC instrumentation has been depending on Differential Refractive Index (DRI) detection, convenient for the analysis of many types of polymer/solvent combinations. However, in the case of polyolefins, a sensitivity limitation is faced as well as difficulties to keep a stable baseline due to the strong signal dependence on Temperature.

In the GPC instrumentation industry, it has been common practice to place the GPC/SEC columns, injector valves and detectors in the same oven compartment, so when requiring to change the loop size, filter, or perform detector maintenance, the whole system needs to be cooled down to prevent column damage; thus, requiring slow cooling and heating rates and demanding long stabilization time before the analysis can be performed.

Little effort has been applied to investigate the chemical composition and molar mass interdependence in the case of polyolefins, and when it was established it demanded off-line FTIR systems or external flow through cells with liquid nitrogen cooled detectors. With these considerations in mind, Polymer Char initiated a few years ago the design of a totally new GPC/SEC system based on a well-known infrared detector (IR4) which provides good stability and sensitivity for the analysis of polyolefins; infrared detection results in equivalent Molar Mass Distributions (MMD) curves to those obtained by DRI and without the presence of negative or spurious peaks after polymer elution.

The use of the IR4 detector in GPC/SEC analysis is today rather common in many laboratories, meaning a significant breakthrough in detection technology. For the first time simultaneous concentration and composition signals were obtained into a single instrument; the composition signal allows to measure branches in PE copolymers, ethylene content in EP copolymers and vinyl acetate in EVA resins, all along the molar mass distribution. This new dimension in GPC analysis (Chemical Composition) comes at a time when new commercial copolymer resins demand such composition–molar mass interdependence analysis.

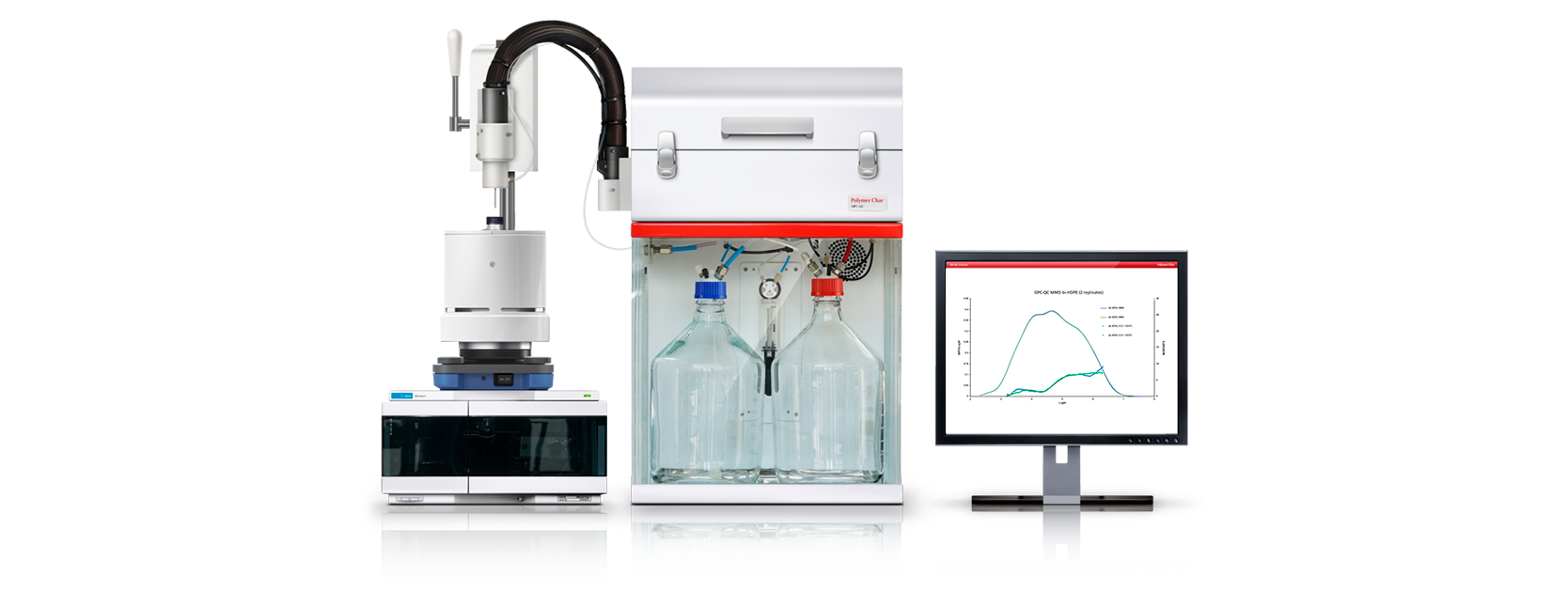

Instrument Description: New GPC-IR

In this application note we describe the full integration of the new infrared detector IR5 MCT, with outstanding sensitivity and stability into the GPC-IR instrument redesigned in 2013.

Besides the IR5 MCT detector and the most advanced sample preparation system, the new GPC-IR incorporates other technological developments to fulfill Polymer Char’s design philosophy based on the principles of highly reliable hardware, full automation, user-friendly operation, easy maintenance, and proper diagnostic tools:

- Three independent thermostated compartments with adjacent walls for reduced length of connecting tubing are included within the main body of the GPC-IR, which also holds all the instrument electronics: independent column oven, injector and filter compartment and detectors compartment.

- Separate high temperature autosampler module, in which sample preparation takes place.

- Solvent management system incorporating Agilent HPLC pump and degasser, syringe dispenser and a software controlled solvent recycling system.

- Differential viscometer and optional DAWN® HELEOS™ II Multiple Angle Light Scattering (MALS) detector from Wyatt Technology®, complementing the IR5 MCT detection, and optional IR4.

- Advanced and comprehensive processing software GPC One which integrates all detectors’ signals in a single package.

- Virtual Instrumentation Control software with advanced diagnostics tools and prepared for remote control access.

Sample Preparation

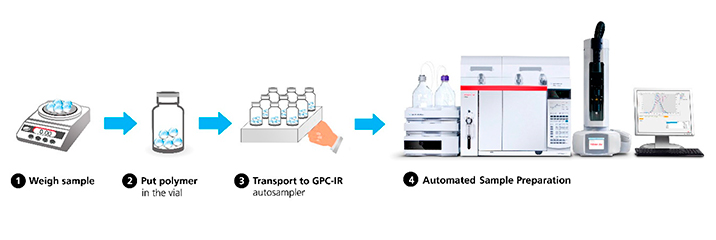

The GPC-IR system has been designed with a fully-automated sample preparation approach, minimizing the user interaction and eliminating manual solvent handling while at the same time, preventing sample degradation. The analyst needs only to weigh the samples into separate vials and bring them into the autosampler tray where they will stay at room temperature waiting for the dissolution step (Figure 2).

Figure 2. GPC-IR Sample Preparation Process.

The autosampler can accommodate 42 vials of 6, 10 or 20mL for better sample preparation. The control software takes care of the overall solvent handling process and dissolution time for each vial; samples stay at high Temperature just the required time for dissolution.

Solvent preheating before vial filling, together with a compact oven design and vial shaking, results in a very efficient but gentle dissolution process.

Sample degradation in polypropylene and in very high molecular weight (MW) polyolefins is minimized. This is possible due to the elimination of oxygen from the vial and solvent through a nitrogen purge and installed degasser, precise control of time and temperature in the dissolution step, and the elimination of stirring bars, which may result in shear degradation.

A significant effort was devoted to developing a fully-automated operational in-line filter media and filtration process which would be reliable and long-lasting for months before requiring exchange.

Filtration is performed in the process of filling the injection loop; therefore, only a small part of the solution needs to be filtered. Once the Injection is performed, the filter is backflushed to waste with significant solvent volume from the syringe to have the filter clean and ready for next sample filtration.

New Integrated Infrared Detector IR5 MCT

In infrared detection of polyolefins, good sensitivity, baseline stability and fast stabilization periods are paramount, as it has been demonstrated by the extensive incorporation of the IR4 detector in existing GPC systems. Besides sensitivity and stability of the concentration signal, infrared detection provides a continuous and simultaneous measurement of chemical composition along the molecular weight distribution.

New developments in infrared technology have allowed us to integrate a highly sensitive Mercury Cadmium Telluride (MCT) detector (thermoelectrically cooled) into the GPC-IR eliminating the need of heated transfer lines. The results obtained show an outstanding improvement in signal to noise ratio over the standard IR4 of around ten times in both concentration and composition signals. Besides sensitivity improvement, the now integrated IR5 MCT is not affected by variations in laboratory temperature due to the carefully controlled detector environment, resulting in superb long term baseline stability.

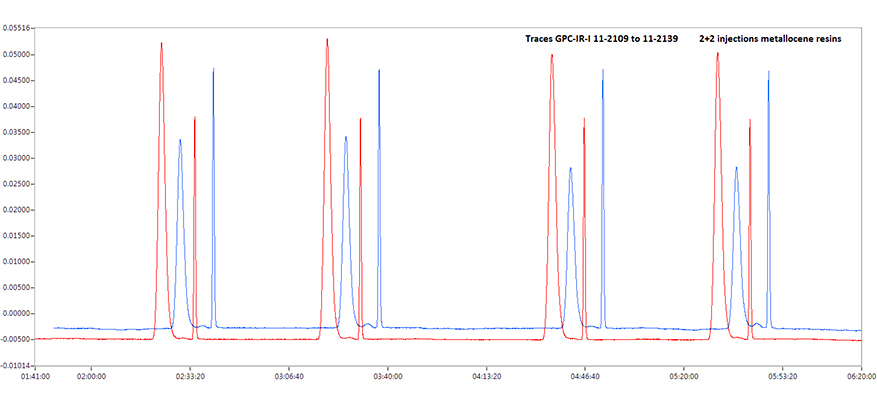

The analysis of two metallocene PE samples, each one by duplicate from the same vial, is shown in Figure 3. An excellent sensitivity and baseline stability can be observed both in concentration as well as composition signals for an injection of 200 microliters of a solution of 2mg/mL in a 3 Agilent PLgel Olexis columns. The good definition of baseline is the basis for precise calculation of MW moments.

Figure 3. Recording baseline of 4 injections (2 per vial) using 3 Agilent PLgel Olexis GPC/SEC columns and 2mg/mL, 200µL loop. Red signal: Concentration. Blue signal: Composition (CH3/1000C emphasis).

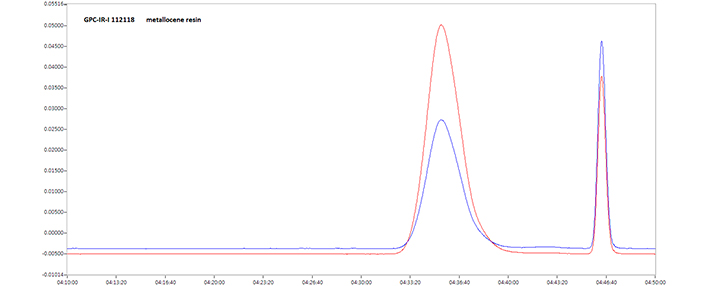

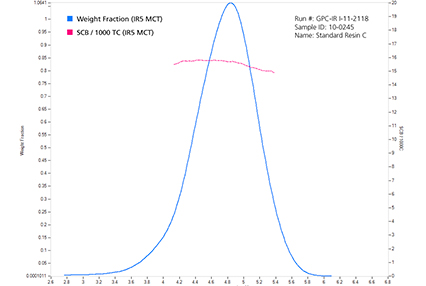

In Figure 4a, an expanded view of one of the curves above is presented without any smoothing to show the good sensitivity and stability achieved. The calculated MMD is shown in Figure 4b with composition-molar mass interdependence.

Figure 4a. Recording baseline of one of the PE analysis of Figure 3. Red signal: Concentration. Blue signal: Composition (CH3/1000C emphasis).

Figure 4b. Calculated MMW of sample of Figure 4a showing the composition – molar mass interdependence.

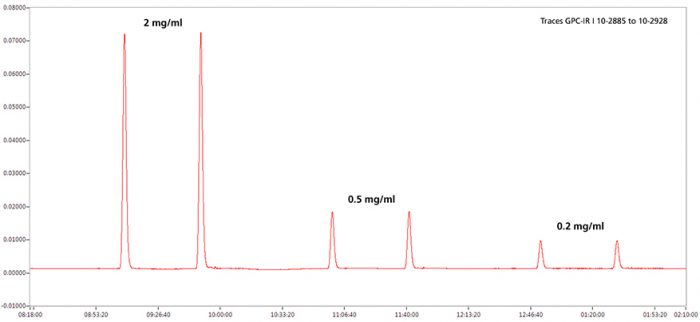

The high sensitivity of the IR5 MCT allows us to reduce the injected amount of sample into the columns preventing viscous fingering effects and damage of columns when analyzing high molecular-weight polyolefins. The repeated analysis of one of the samples above by lowering the concentration down to 0.2mg/mL is presented in Figure 5 maintaining a good s/n ratio and baseline stability.

Figure 5. Recording baseline of duplicate PE analysis at different concentrations and with 200 µL loop.

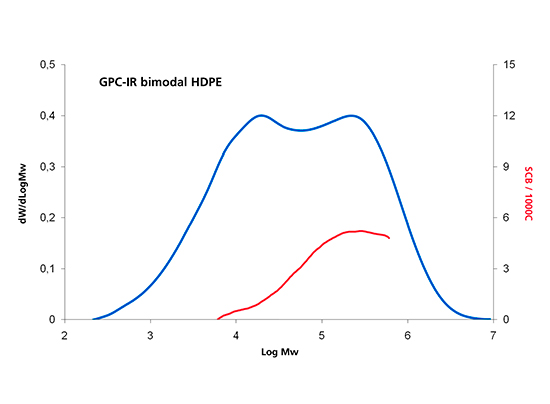

A significant advantage of using the integrated IR5 MCT detector is in the composition analysis along the molar mass of PE with very low number of branches such as in the case in HDPE pipe resins grades, which previously required the use of FTIR with detection at liquid nitrogen temperatures. The analysis of a pipe resin with a low number of branches is shown in Figure 6 with a limit of detection of less than 1 CH3/1000C.

Figure 6. Analysis of a bimodal HDPE pipe resin grade with low number of branches. GPC-IR run at standard conditions 200µL injection of 2mg/mL with 3 Agilent PLgel Olexis columns.

Conclusions

The integration of the new IR5 MCT detector into GPC-IR results in an outstanding sensitivity in both concentration and composition signals; this is an order of magnitude better than the existing IR4 detector. The new design of the IR5 MCT makes it also very insensitive towards external temperature changes and an order of magnitude improvement in baseline stability has been achieved as well; never before have stability and sensitivity in GPC analysis of polyolefins reached such a mark.

A good baseline definition is the basis for precise MMD analysis and calculation of MW moments. The possibility to reduce the amount of polymer injected when dealing with high MW materials reduces plugging problems, extends column life, and eliminates or minimizes viscous fingering spurious effects.

Full automation of the sample preparation with special care to avoid sample degradation is presented in the new GPC-IR design.