GPC-QC

Simplified and fully automated GPC/SEC instrument aimed at quality control laboratories in polyolefin production plants

Simplified and fully automated GPC/SEC instrument aimed at quality control laboratories in polyolefin production plants

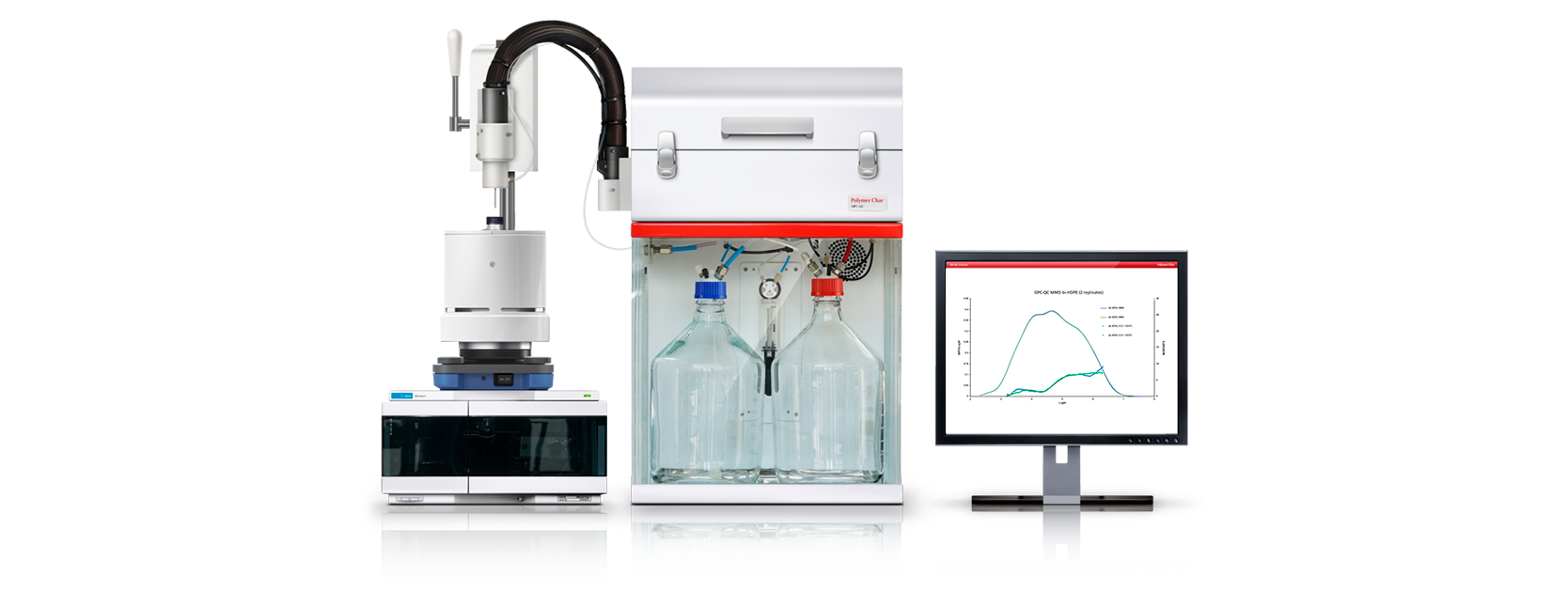

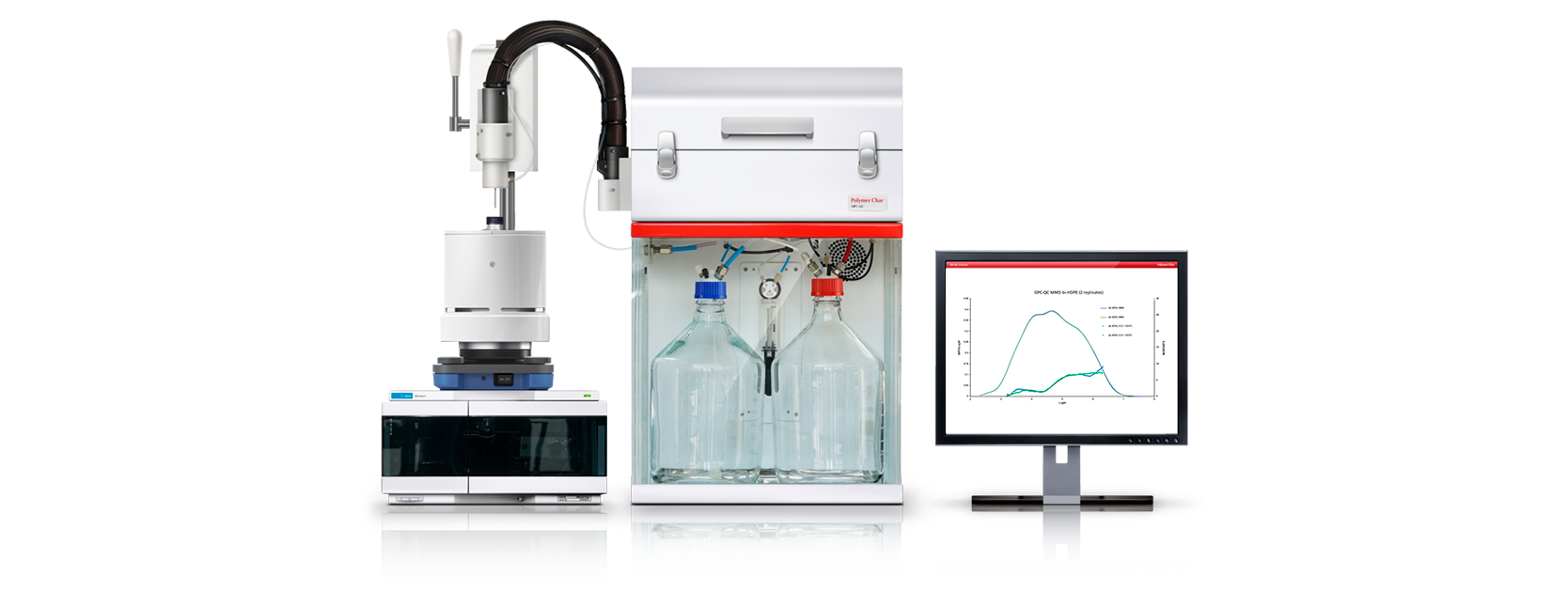

GPC-QC is a compact, high-temperature Gel Permeation Chromatography (GPC) instrument for quality control in polyolefin production plants.

GPC-QC has a simple and reliable approach based on Polymer Char’s Quality Control platform. It provides a robust and precise microstructural characterization to fulfill the industry’s requirements towards a more uniform production and tighter specification ranges.

For quality control purposes, the industry has traditionally relied on bulk parameters such as Melt Flow Index and Density, which represent average molecular weight and average chemical composition, respectively.

With the development of more complex polyolefins, Melt Flow Index and Density start to show their limitations, as these physical parameters alone may not explain the resin’s performance. GPC-QC can provide significant value to the production control lab by measuring the whole Molecular Weight Distribution (MWD) of the sample.

AUTOMATION:

GPC-QC delivers the complete MWD for one sample through a simplified workflow, while keeping a fully automated sample preparation and an analysis free of manual solvent handling throughout the entire process. Depending on the sample and analytical conditions, the complete analysis can take as little as 30-40 minutes including dissolution.

GPC-QC design principles and operation

DETECTION:

The Infrared (IR) detection, implemented in the instrument through Polymer Char’s integrated IR4 or IR6 detectors, both highly stable, contributing to the overall reliability of the instrument. The IR detector also provides simultaneous chemical composition information, which is key for controlling the production of heterogeneous resins.

For a truly complete analysis, the instrument can also measure the sample’s Intrinsic Viscosity (IV) by means of a built-in dual-capillary viscometer.

APPLICATIONS:

Important applications for GPC-QC are:

GPC/SEC METHOD: The GPC-QC complies with the ISO 16014-4 and ASTM D6474 methods for High-Temperature GPC measurement.

· Simple and reliable design for Quality Control environments.

· Full automation of the entire analytical process.

· One sample analyzed in 30 minutes including dissolution.

· 100 mL vials to ensure good sample representativity.

· IR4 or IR5 detectors for Concentration and Short Chain Branching (SCB) information (IR detectors comparison)

· Optional incorporation of a dual-capillary viscometer.

· Comprehensive results (MWD, SCB, IV).

· Outstanding precision thanks to the instrument's full automation and the detectors’ robustness.

The following are the detectors available for GPC-QC:

IR4 is the standard detector integrated by default in all the Polymer Char analytical instruments. IR4 is a dual-wavelength infrared detector, which uses the principle of infrared absorption spectroscopy to measure the concentration and composition in polyolefins.

IR6 is the latest infrared detector developed by Polymer Char. It has superior performance and sensitivity and the additional capability of measuring carbonyl group in the band of 1740 cm-1. The IR6 detector is recommended for users that want to analyze EVA, EBA, and other polyolefins which have carbonyl group present in the 1740 cm-1 band.

A two-capillary serial Viscometer can be included in the GPC-QC configuration to provide Intrinsic Viscosity and Long-chain Branching data. Intrinsic viscosity is directly related to the processing behavior and properties of the polymer. The viscometer design is robust and well suited for the quality control environment.

The GPC-QC software controls the whole process, from filling the vials with solvent, to dissolving and injecting the sample. Therefore, the end-user tasks only consist of weighing the sample in the vial and placing it in the instrument. From that point on, all the needed steps are performed by the instrument with no manual intervention.

The GPC-QC Software has been built as a Virtual Instrument, with the possibility of operating all the instrument hardware parts from the computer, and receiving feedback from all the actions and detectors signals.

The One Software package, developed in collaboration with the polyolefin industry’s leaders, provides the most powerful data processing platform available in the market.

To request a demo, please contact us

Read more about One Software

The purpose of a GPC-QC instrument is the analysis of the Molecular Weight Distribution (or GPC/SEC analysis) to control the quality of polyolefins during their production process. This technique offers complete information about the microstructure of the resin, helping manufacturers achieve a more uniform production.

GPC-QC is designed as a simple and compact high-temperature GPC instrument, easy to operate in polyolefin manufacturing lines.

For a high-temperature GPC/SEC instrument aimed at research and development labs, please see Polymer Char's GPC-IR

One sample is analyzed in each run. The complete process (including dissolution) is carried out in about 30-40 minutes with standard conditions. The total analysis time will depend on the number of GPC columns, detectors, and injections done per vial, dissolution time, and flow rate.

To learn more about analysis time, sample dissolution, solvent consumption, and other practical considerations, click the link below:

60mg are used as standard for preparing a 1mg/mL solution in the GPC-QC bottles.

1,2,4-Trichlorobenzene (TCB) and Orto-Dichlorobenzene (oDCB) are the typical solvents used with GPC-QC. To use other solvents please consult Polymer Char first.

The only manual tasks required are weighing the dry samples and putting them inside the bottles. The rest of the steps are performed by the instrument automatically: filling the bottle with solvent, sample dissolution, injection, as well as self-cleaning. Therefore, when a run is finished, another one can be started inmediately.

You will not need to handle solvents manually at any time, the instrument handles all the solvent-involving tasks.

For a completely automated solvent handling process, Polymer Char also offers a Solvent Handling Trolley to transfer fresh and waste solvent from the solvent station to the instruments.

GPC-QC is designed for the difficult task of polyolefin analysis at high temperature with chlorinated solvents. The instrument with the standard IR detector can be used to analyze all polymers soluble in chlorinated solvents (TCB, o-DCB) which have C-H bonds in the backbone.

Among the most common samples analyzed by GPC-QC are bimodal high-density polyethylene made in a dual-reactor process and ultra-high molar mass resins.

GPC-QC incorporates an infrared (IR) detector to collect concentration chromatograms after the GPC column separation. As well as concentration, the IR detector can simultaneously provide chemical composition (or Short-chain Branching, or comonomer content) information of the sample.

GPC-QC can integrate Polymer Char’s IR4 and IR5 infrared detectors. The use of the high-performance IR5 detector is recommended for quality control applications, thanks to the fast stabilization time, stable baseline, and good sensitivity.

For a truly complete analysis, the instrument can also measure intrinsic viscosity by means of a built-in dual-capillary viscometer that can be incorporated as an additional feature.

The GPC-QC instrument incorporates a GPC column, which is located in the instrument's top oven, together with the valve and other components.

After each injection, the data can be accessed and processed through the GPC-QC Software database. Polymer Char’s GPC One is currently the most comprehensive GPC Calculations Software package, because it integrates all the detectors signals and can be customized to include in-house data-processing procedures. A reporting tool has also been developed to generate Excel reports adapted to each user's needs.

The capacity of the vials is 100mL. They are usually filled with 60mL, from which up to five injections can be done. The injection loop has a standard volume of 200 uL, but it can be adjusted according to the user's needs.

Preventive maintenance is recommended once a year. For more information, click on the link below.

You can request a quotation via the Contact Form or by sending us an email to sales@polymerchar.com

Thank you for your interest. If you would like to receive more information or want to request a quotation please complete this form.

This site uses cookies to give you a better browsing experience. If you continue

browsing this site we understand that you accept our use of cookies.

For more information,

please visit our Cookies Policy. You can configure which

cookies you accept by ticking the next options: