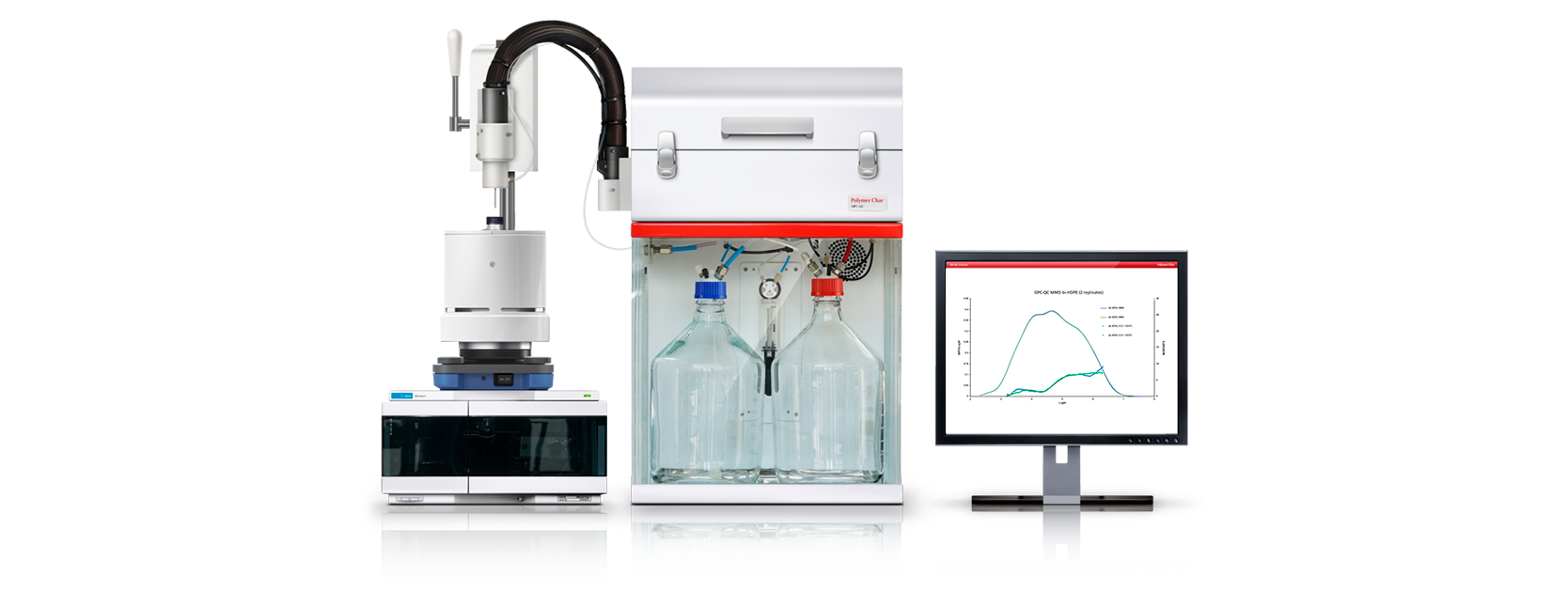

CRYSTEX® 42 Features

The CRYSTEX 42 eliminates all the manual steps involved in the traditional gravimetric method (dissolution, crystallization, filtration, aliquot, evaporation, drying), as it automates the complete process. No manual work is done with CRYSTEX 42.

The measure of the soluble fraction % is obtained without accurate sample weighing or manual handling of solvents. With CRYSTEX QC, no external filtration or solvent evaporation are necessary.

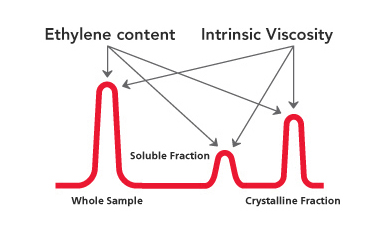

The same analytical cycle also measures the Ethylene content and Intrinsic Viscosity for the Soluble Fraction, the Crystalline Fraction, and the Whole sample.

The CRYSTEX® method is included in the ISO 16152:2022 as an automated method for the determination of xylene-soluble matter in polypropylene.

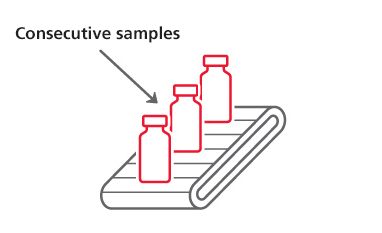

Automated analysis of consecutive samples of smaller amounts (160mg). The full automation system can process multiple consecutive samples without manual intervention or supervision.

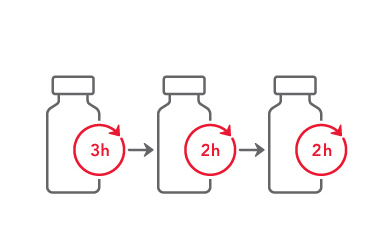

The dissolution and full analysis of the first sample is completed within 3 hours, all of the samples that follow are analyzed every 2 hours.

The size of the CRYSTEX 42 vials is of a 20ml capacity for low solvent consumption.

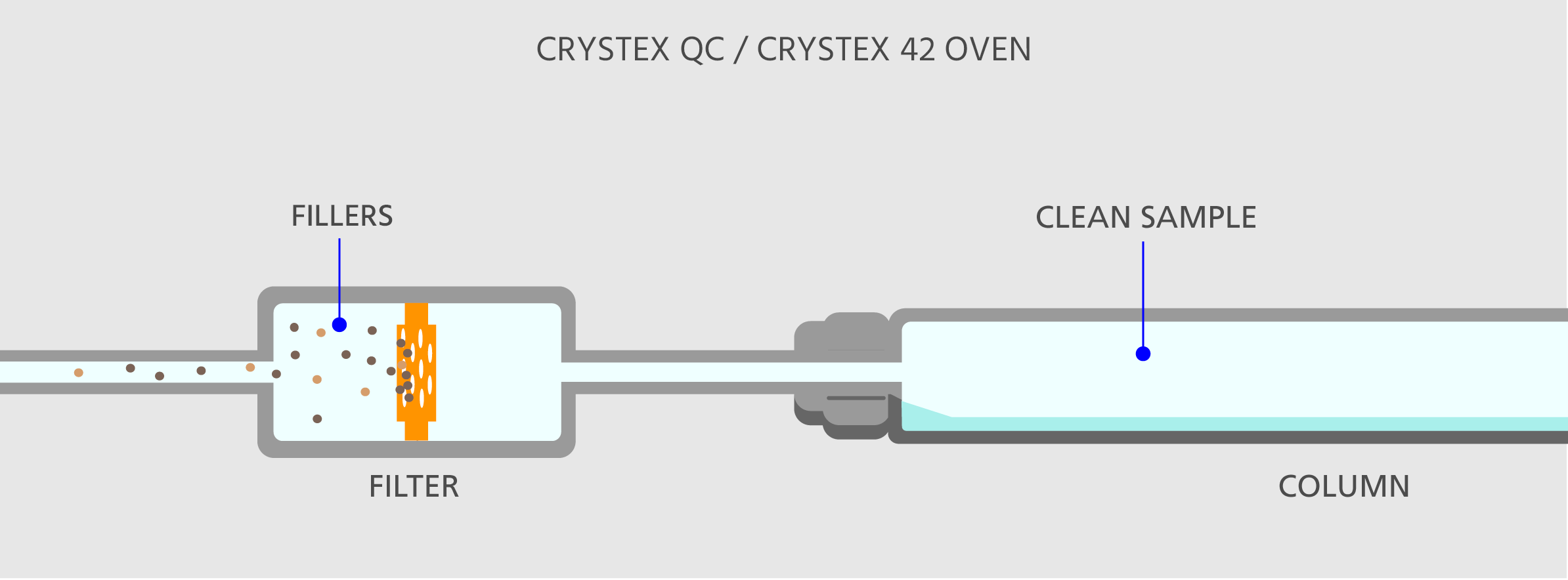

An in-line filter can be incorporated in case of analyzing recyclates or other polyolefins with pigments, or fillers such as talc, mica or others.

Different dissolution bottle sizes are available (240ml, 120ml and 60ml). Compatible solvents for CRYSTEX QC are TCB and oDCB. For other solvents, please ask Polymer Char.

CRYSTEX® 42 Detectors

The following are the detectors available for CRYSTEX® 42:

Viscometer

CRYSTEX® 42 can be configured with a highly sensitive Two-Capillary Relative Viscometer to provide intrinsic viscosity results of the whole sample, the amorphous fraction, and the crystalline fraction.

CRYSTEX® 42 Software

CRYSTEX® 42 is controlled by an intuitive and easy-to-use software that automates the analytical process and provides tools for instrument maintenance and advanced operations.

Two operation modes are available in the CRYSTEX® 42 software: Operator and Administrator. In the Operator Mode, the software allows routine analysis to be performed using the pre-defined Soubles Method, and the results are automatically generated in a report. Therefore, starting a run only involves putting the pellets or powder inside the analysis bottle and starting the software. In about 2 hours, the whole analytical process will be completed, including sample dissolution and analysis. The Results Report is automatically produced on the computer screen. The software has been built as a Virtual Instrument that allows the operation of the hardware parts from the computer and the reception of feedback from all the actions and the detectors’ signals.

The user doesn’t need to work manually at a high-temperature nor handle solvents during any maintenance or diagnosis tasks. For all the data processing, the One Software package is used. This software provides the calibration methods, and the results and calculations. The results from all the analyzed samples are stored in separate files in the computer’s hard disk and organized in folders for convenient management of all the historical data.

The Xylene Solubles percentage is directly provided, as well as the concentration measured by the infrared detector; thus, there is no need for accurate sample weighing before starting the process. When additional detectors are incorporated into the CRYSTEX® 42 equipment, intrinsic viscosity results and ethylene (C2) content will be shown per sample as well, both for the parent sample and for the amorphous and crystalline fractions.

To request a demo, please contact us

Read more about One Software

CRYSTEX® 42 FAQs

These two instruments automate the technique of the Xylene Solubles test. They are intended to measure the amorphous fraction of polypropylene and ethylene-propylene copolymers. The accuracy and precision of the Xylene Solubles test are very important to the process and product specifications of the resultant materials.

Traditionally, this test has been done using the gravimetric method, which requires manual operation along the whole process. As a result, the precision is poor and the procedure is time consuming and not safe.

Polymer Char’s CRYSTEX 42 and CRYSTEX QC instruments automate this technique obtaining high precision and accuracy in the results as well as avoiding manual solvents handling.

While CRYSTEX® QC was designed to be installed in each production plant to monitor in real time the process or the grade changes analyzing a significant amount of powder sample (up to 4 grams), CRYSTEX® 42, thanks to the incorporation of a high temperature autosampler with 42 positions, becomes a perfect complement to be used in a central lab, where large batches of pelletized more homogeneous samples need to be analyzed.

CRYSTEX® 42 and CRYSTEX® QC are analytical instruments designed to measure the Soluble Fraction percentage in a fully automated way, but they don't provide any physical fraction. For this purpose, please read about PREP mc2 or PREP C20.

CRYSTEX® 42 has an autosampler with 42 positions. The amount of samples it can run consecutively depends on the conditions of the analysis. Dissolution and full analysis of the first sample completed in three hours. For the subsequent samples, it takes about two hours.

One sample is performed in each run and complete process, including dissolution is carried out in about 2.5 hours.

The standard amount used in CRYSTEX® 42 analysis is around 160mg per sample and in CRYSTEX® QC is 2g.

Due to the fact that the exact concentration is measured by the infrared detector during the analysis, there is no need of using the balance at all. Up to half a gram can be used for overcoming sample heterogeneity issues.

1,2,4-Trichlorobenzene (TCB) and Orto-Dichlorobenzene (oDCB) are the most used solvents. To use other solvents please consult Polymer Char first.

No samples preparation is required by the user but putting the dry samples inside the vials in case of CRYSTEX® 42 and in the bottle in case of the CRYSTEX QC (weighing doesn’t need to be precise). The rest of the steps are performed by the instrument automatically: vials filling, dissolution, crystallization, final cleaning, etc. Therefore, when a sample analysis is finished, another one can be followed immediately.

Yes, both instruments obtain the SF% without the use of Xylene. It has been shown that there is a good correlation between soluble fraction measured in Xylene and in other solvents. Therefore, by applying the proper calibration, the results obtained in other solvents can be translated to Xylene.

Solvents don’t need to be handled at any time; the whole process is fully automated, the instrument is in charge of all the needed steps: vials filling, dissolution, crystallization, final cleaning, etc.

This instrument is specially designed for the determination of the Soluble Fraction in polypropylene resins but polyethylene can be analyzed as well.

CRYSTEX® 42 and CRYSTEX® QC incorporate an infrared detector to measure the concentration of the solution both at high temperature when the sample is 100% dissolved and also at room temperature, to measure the percentage of the sample which remains in the solution after the crystallization cycle (rubber content). This detector is Polymer Char’s IR4 in its OEM version and therefore a composition sensor could be incorporated as well, to measure the methyls or carbonyls content on the whole sample and on the amorphous fraction.

A capillary viscometer and/or a composition sensor can be coupled to CRYSTEX® 42 or CRYSTEX® QC without adding complexity to the process. Therefore, additional information about the intrinsic viscosity and/or ethylene content on the whole sample and on the rubber content can be obtained with a similar analysis time.

Read more about CRYSTEX 42 Software

The soluble fraction results of CRYSTEX® 42 show an excellent correlation with those obtained with the gravimetric method for a wide selection of PP resins, with the added advantage that CRYSTEX® 42 has better reproducibility thanks to the automation of the system. CRYSTEX® 42 shows a standard deviation (std) of less than 0.1%, much lower than indicated by the standard methods.

Request More Information about CRYSTEX® 42

Thank you for your interest. If you would like to receive more information or want to request a quotation please complete this form.

This site uses cookies to give you a better browsing experience. If you continue

browsing this site we understand that you accept our use of cookies.

For more information,

please visit our Cookies Policy. You can configure which

cookies you accept by ticking the next options: