CRYSTAF

Crystallization Analysis Fractionation.

Innovative and fast approach to the Chemical Composition Distribution analysis in Polyolefins needing a single temperature.

Crystallization Analysis Fractionation.

Innovative and fast approach to the Chemical Composition Distribution analysis in Polyolefins needing a single temperature.

Crystallization Analysis Fractionation (CRYSTAF) is a fully-automated instrument for the fast measurement of the Chemical Composition Distribution in Polyolefins. The instrument performs the Crystallization Analysis Fractionation technique to separate the polymer by its comonomer content.

The virtual instrumentation software controls the full process, therefore, no manpower is required. Dry samples are put in the crystallization vessels and the instrument fills them with solvent and performs the dissolution, crystallization, sampling, and cleaning.

Up to five different samples can be analyzed at a time in an 8-hour period under standard conditions. The results of the Chemical Composition Distribution are obtained directly from the software. At the end of the process, the vessels and lines are automatically cleaned and the instrument is ready to analyze more samples.

CRYSTAF is a technique developed and patented by The Dow Chemical Company and licensed to Polymer Char.

Up to 5 samples can be analyzed simultaneously in 8 hours under standard conditions. The fully-automated process includes self-cleaning of the lines and vessels, and no manpower and manual handling of solvents is required during the whole process.

The CRYSTAF technique is so simple that the analysis is performed and complete with the crystallization cycle only.

The instrument can be calibrated to obtain the chemical composition distribution curve in comonomer content units.

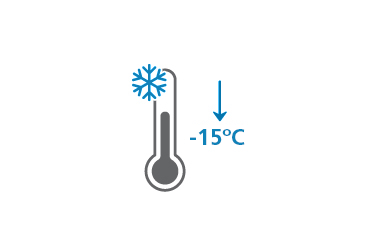

For low crystallinity samples, CRYSTAF can go as low as -15ºC

For more analytical power, the instrument can be turned into a CRYSTAF-TREF, adding the elution step to the analysis.

The following are the detectors available for CRYSTAF:

The IR4 is the standard Detector integrated by default in all the Polymer Char analytical instruments. IR4 is a dual-wavelength infrared detector, which uses the principle of infrared absorption spectroscopy to measure the concentration and composition in polyolefins.

The CRYSTAF Software is specifically developed for controlling and monitoring the automated CRYSTAF technique. It offers two operation modes: automated analysis and manual action. In the automated mode, an easy and complete interface defines all the conditions for the CRYSTAF analysis, such as the crystallization ramps, temperatures, times or volumes; to be adapted to all kind of Polyolefins and research studies by CRYSTAF technique.

Furthermore, a set of standard methods are previously saved in the instrument to be used by the analyst for the routine sample analysis, based on Polymer Char’s standard conditions. The user’s methods can also be saved and recovered for successive analyses.

On the other hand, the manual action operation offers the full control of the instrument, thought to be used as a fast and powerful diagnosis tool directly by the user and also by Polymer Char service engineers.

The Calculations screen is linked to the instrument database to facilitate the samples results organization.

To request a demo, please contact us

Read more about One Software

CRYSTAF technique (Crystallization Analysis Fractionation) was developed to obtain the Chemical Composition Distribution curve during the crystallization step. Therefore, at the end of a CRYSTAF run, a distribution in concentration versus temperature of crystallization is obtained.

CRYSTAF is an analytical instrument which was designed to obtain the chemical composition distribution curve, but it doesn’t provide any physical fraction. For this purpose, please read about PREP mc2.

Up to 5 samples can be run in about 8 hours with no supervision required. After the run, an automated cleaning is performed by the instrument and therefore it is ready to start another run immediately.

The standard amount used in CRYSTAF analysis is around 40mg per sample, therefore the instrument can be used both for research and also for quality control.

1,2,4-Trichlorobenzene (TCB) and Orto-Dichlorobenzene (oDCB) are the most used solvents. To use other solvents please consult Polymer Char first.

No samples preparation is required by the user but weighing the dry samples and putting them inside of the crystallization vessels. The rest of the steps are performed by the instrument automatically: filling, dissolution, crystallization, final cleaning, etc. Therefore, when a run is finished, another one can be started immediately.

Solvents don’t need to be handled at any time; the whole process is fully automated and the instrument performs the rest of all the needed steps: solvent filling, dissolution, crystallization, final cleaning, etc. So after a run, the instrument is ready to start again immediately.

LLDPE, LDPE, HDPE, PP, E-P copolymers, multicatalyst reactor resins, and any semicrystalline polymer soluble in TCB or oDCB, giving response to C-H absorption.

CRYSTAF incorporates an infrared detector to measure the concentration of the solution while the temperature is decreasing in the crystallization cycle. This detector is Polymer Char’s IR4 in its OEM version and therefore a composition sensor can be incorporated as well to obtain methyls or carbonyls content information.

The CRYSTAF Software incorporates a database to easily access all the analyzed samples, which is connected to the calculations and results screens. Any result can be accessed and reviewed at any time, even when the instrument is running other samples. Comparative results among different samples are also possible.

CRYSTAF obtains the CCD curve during the crystallization step, and TREF does need an additional temperature cycle called elution to obtain the same results.

TREF obtains the CCD curve directly and in a continuous way, meanwhile the CRYSTAF technique does so in a discontinuous way: a series of data points from the cumulative composition distribution curve are actually measured and used to obtain the differential distribution by means of a smoothing splines fitting algorithm.

CRYSTAF obtains the CCD curve during the crystallization process, and TREF does need an extra temperature cycle called elution to obtain the same results. The results obtained with both techniques are very similar but when expressed in temperature scale there exists a shift to lower temperatures in CRYSTAF due to undercooling effects.

Results obtained by CRYSTAF or by TREF will be equivalent in most of the polyolefins; therefore only one of the techniques is enough in most cases. However, for some specific kind of polyolefin blends, separation might be better achieved by CRYSTAF or by TREF due to the different behavior of the components in composition. In this sense, having both techniques available, the best possible separation will be achieved for every sample.

Thank you for your interest. If you would like to receive more information or want to request a quotation please complete this form.

Try our Analytical Services. Click here for more information.

This site uses cookies to give you a better browsing experience. If you continue

browsing this site we understand that you accept our use of cookies.

For more information,

please visit our Cookies Policy. You can configure which

cookies you accept by ticking the next options: