How to choose the most appropriate combination of detectors for high temperature SEC/GPC analysis of polyolefins

- January, 26 2021

- Category: GPC/SEC

High Temperature Size Exclusion Chromatography (SEC) – also called Gel Permeation Chromatography (GPC) – is the most widespread technique to characterize the microstructure of polymers.

Different detector-configurations can be used with SEC instrumentation, each of them contributing to the resin’s characterization in a different manner. In this guide we will cover the industry’s most used detectors for the characterization of polyolefins by SEC/GPC technique: two types of concentration detectors (DRI and IR), capillary Viscometers, and static Light Scattering detectors.

Single-detector systems are too limited in most scenarios, while multi-detector systems provide the synergy from the group. How to choose the best detector-configuration according to each laboratory’s characterization needs is not so obvious, and different factors need to be considered: the types of polymers to analyze, the information sought, the detector’s complexity, and the total cost of ownership.

Concentration Detectors: Infrared and Differential Refractive Index

Both Infrared (IR) and Differential Refractive Index (DRI) detectors measure the concentration of the polymer solution coming from the SEC columns at the different retention times, which then translates into the Molecular Weight Distribution (MWD) curve of that polymer resin.

In a DRI detector, there is a change in the direction of a beam of light due to the difference in refractive index of polymer solution coming out of the columns compared to that of the pure solvent. That angular change is measured as a small displacement of the beam reaching a sensor proportional of the refractive index difference, in turn proportional to the solute concentration.

The main advantage of DRI detectors is that they are universal. This means that they can be used for almost any polymers and any solvents, therefore, their range of possible applications depends only on the user’s knowledge and on whichever practical constraints exist related to solvents, columns, temperatures, and rest of analytical conditions. On the other hand, the main disadvantages of DRI detectors are:

- Their low sensitivity, which depends on the dn/dc of the polymer in the solvent.

- They are extremely susceptible to temperature and pressure/flow changes, and they are generally difficult to stabilize.

- They produce spurious peaks, which can hamper calculations when setting the integration limits.

Infrared detectors used in SEC/GPC generate absorbance chromatograms at specific bands in the MID-IR. IR radiation is absorbed by the chemical bonds in the polymer molecule at specific wavelengths, and the reduction of light intensity at the sensing element is detected and converted to absorbance units, proportional to the solute concentration according to Beer’s Law.

When it comes to polyolefin analysis, Infrared technology has proven to be the most appropriate solution due to its compelling advantages:

- Its peaks are always positive, and the baseline is naturally clean. This facilitates the integration of peaks for data processing.

- Infrared detectors do not need stabilization time.

- Most importantly, Infrared detectors add a new dimension to the standard SEC analysis as they can also detect the Short-chain Branching (SCB). This additional information may set apart polyolefins that have a very similar Molecular Weight Distribution, but a different structure in terms of comonomer incorporation, as shown here.

Historically, Differential Refractive Index detectors have been the main detector used in Size Exclusion Chromatography for polyolefins. However, the important advantages of IR detection over DRI motivated the approach followed by Polymer Char: to develop its own proprietary Infrared Detectors specifically focused on the characterization of polyolefin resins. Therefore, IR detectors are used as concentration detectors in all Polymer Char’s separation techniques, including SEC/GPC (by GPC-IR and GPC-QC instruments, and analytical services).

For more information about Polymer Char’s Infrared detectors you can read our IR4, IR5, and IR6 comparison.

Poster: Direct comparison of IR and DRI detector for HT-GPC of Polyolefins

Viscometer Detector

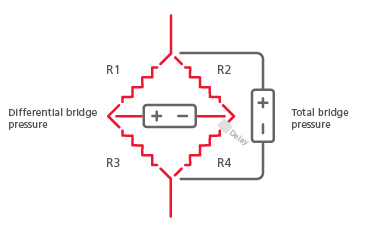

A capillary viscometer is an ideal complement to the concentration detector for an accurate determination of molecular weight distribution and averages by SEC. The most common viscometer configuration is the 4-capillary differential viscometer, as seen in the diagram below. This configuration delivers an excellent sensitivity, an attribute required for such a demanding application.

Schematic diagram of a 4-capillary differential bridge viscometer.

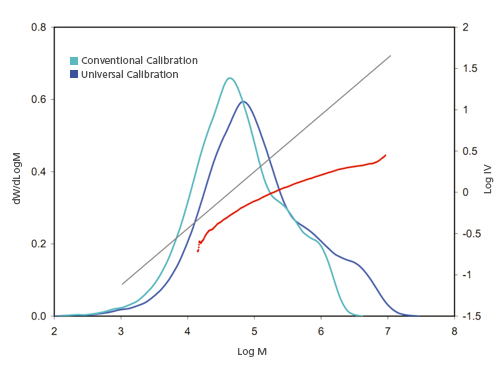

The advantage of having an online viscometer is that it allows for the application of the Universal Calibration principle, thus overcoming the limitation of the single-detector relative SEC methods when applied to branched polymers such as LDPE. This is shown in the image below:

Universal Calibration (dark blue) vs Conventional Calibration (light blue).

A viscometer detector is also used for the analysis of Long-chain Branching (LCB), by comparing the Mark-Houwink graphs of branched against linear reference samples.

The combination of a concentration detector with an online viscometer in a High Temperature SEC instrument significantly expands the possibilities of the SEC technique, because it provides true Molecular Weight Distribution and averages, SCB (when using Infrared detector), Intrinsic Viscosity (IV), and LCB.

Infrared + viscometer in a SEC instrument is the ideal detector configuration for most polyolefins, but especially for ethylene-propylene copolymers and for LDPE samples. This is because it provides universal calibration, which can be applied precisely for any type of microstructure – even the branched samples and copolymers – when conventional calibration fails.

A Viscometer detector is a worthy investment in a SEC system for polyolefin analysis. Certain practical considerations must be taken into account to keep it in good condition and to prevent obstructions in the capillaries, however, integrated viscometer detectors are typically affordable and a worthwhile investment when considering the additional results they provide.

Light Scattering Detector

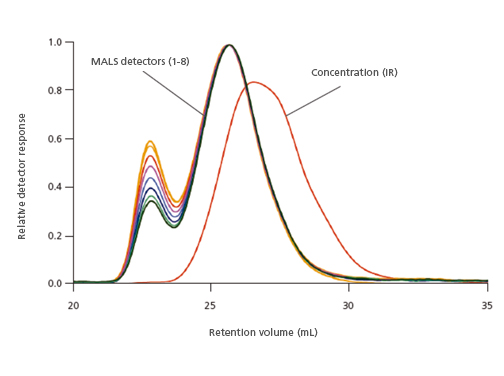

When coupling a Multi-angle light scattering (MALS) detector to a SEC instrument, complementary information is obtained towards a more complete characterization of molar mass distributions and molecular architecture of polymers.

With MALS detectors, Debye plots can be acquired at every SEC-separated slice, and the extrapolation to zero angle is calculated. The zero-angle intercept provides absolute molar mass measurement, while the radius of gyration (Rg) is calculated from the zero-angle slope.

Chromatograms from the MALS detectors obtained at different scattering angles, and concentration by IR, for a branched LDPE material.

When coupling a MALS detector to a SEC instrument, absolute molar mass can be obtained without going through a column calibration process, and the results obtained are absolute Mw and MWD, SCB (when using Infrared detector), Rg, and LCB.

Infrared + MALS is the detector configuration recommended for UHMWPE samples. These samples require significantly lower concentration levels to protect the instrument lines and the SEC columns from clogging. Using such low concentration levels require detectors with high sensitivity, like Infrared and Light Scattering detectors.

From a practical point of view, the most important advantage of using a MALS detector is that the column calibration process can be skipped, with the subsequent saving in time, reference materials, and solvent.

MALS detectors add valuable information to SEC analyses but, when deciding whether to invest in one, it is also worth considering their potential drawbacks:

- MALS detectors are usually expensive.

- They add complexity to the SEC system and demand a high level of expertise.

- They require extra precautions to keep a clean detector cell and noise-free baseline, such as prefiltering the samples that have carbon black or other additives of small particle size, and having an uninterrupted, high flow of solvent through the SEC system during stand-by.

Triple-detector Configuration

The triple-detector configuration is achieved by combining a Concentration detector (IR/DRI), a Viscometer detector, and a Light Scattering detector in the SEC or GPC system. This powerful configuration delivers Mw, MWD, SCB (when using Infrared detector), IV, Rg, and LCB results.

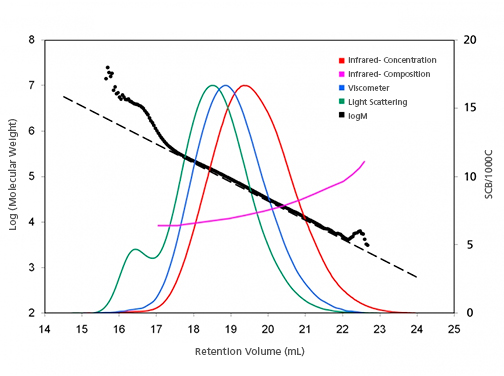

GPC-IR analysis with triple-detection configuration (IR5, Viscometer, and Light Scattering)

Size Exclusion Chromatography with triple detection is especially recommended for samples with a very low LCB level, because the Mark-Houwink plot calculation will be the most precise one.

Summary

A summary of the most appropriate combination of SEC/GPC detectors for each type of polyolefin sample can be found in the table below. Depending on the detectors included in the system, more of less detailed and accurate information will be extracted from the SEC analysis:

| Detectors | Samples | Results | Comments |

|---|---|---|---|

| Concentration (IR or DRI) | All Polyolefins, especially bi-HDPE, LLDPE and homopolymers | MWD, Composition (SCB, only with IR Detector) | Basic configuration |

| Concentration (IR or DRI) + Viscometer | All polyolefins, especially heterogeneous copolymers, LDPE and LLDPE | Mw, IV, SCB (only with IR Detector), MWD, LCB | Recommended configuration |

| Concentration (IR or DRI) + Light Scattering | All polyolefins, especially UHMWPE | Mw, MWD, SCB (only with IR Detector), Rg, LCB | Less common configuration |

| Concentration (IR or DRI) + V + LS “Triple-detector configuration” | All polyolefins, especially for those with most complex structures | Mw, MWD, IV, SCB (only with IR Detector), LCB | Most complex configuration |

Single detector methods (using DRI or single-band IR detectors) provide the Molecular Weight Distribution under some assumptions, while Low-angle and Multi-angle Light Scattering detectors provide absolute MWD and weight average molar mass. When we add a viscometer to a SEC instrument, we can obtain true MWD using Universal Calibration, as well as IVD and LCB; and the triple-detector methods combine all the previous results.

When using a multiple-band IR detector as the concentration detector in the system, a new dimension is added to the SEC analysis: the chemical composition, (SCB or comonomer content). Thus, the most complete SEC system would consist of a triple detector combination using a multiple-band IR detector.