September 2014

By N. Mayo, R. Chiva, B. Monrabal. Polymer Char, Valencia, Spain.

Introduction

Preparative fractionation in a column packed with an inert support is a long used technique for the characterization of polyolefins as it facilitates the analysis of the fractions to obtain the bivariate distribution of a resin.

For decades, fractionation has been an important but challenging and tedious technique because it requires handling manually large volumes of toxic solvents at high temperature. Thus, the significant amount of time and effort demanded for the operation called for an automatic equipment that avoided solvent handling by the analyst. In 1996, a collaborative effort between a German Chemical Company and Polymer Char resulted in the development of the instrument PREP mc2, an automated technique that was able to fractionate polyolefins according to their chemical composition (by temperature rising elution fractionation, TREF or by crystallization analysis fractionation, CRYSTAF) or according to their molar mass. Samples were placed into vessels and fractionation performed automatically according to the selected method in less than 24 hours. Nevertheless, with this method, fractionation takes place with the absence of a support and it has started to become evident that for some polymers, when fractionating by TREF, a support for the solution to adhere to is critical for a good separation of the fractions, as is the case with newly developed multiple reactor-catalyst resins.

As a response, Polymer Char has introduced the new PREP C20, a column-based equipment for preparative fractionation of up to 20 grams of polymer. It has been developed for polyolefins but it can be used for other polymers depending on the solvents needed for dissolution.

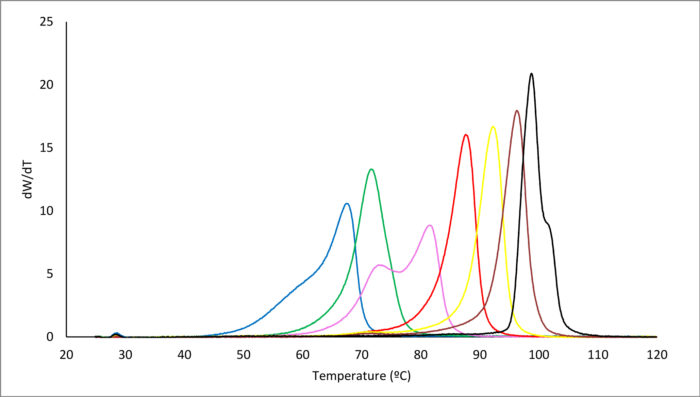

By adding a column as support for the solution to crystallize, the separation for each of the fractions is more appropriate for those types of new resins. Figure 1 illustrates a case of fractionation of a complex dual reactor LLDPE polyolefin that was not possible to fractionate properly without using a support.

Figure1. Fractionation of a complex sample using a column based preparative equipment. Separation of the fractions is achieved.

The instrument works as a pilot plant in complete automatic mode, eliminating the need of manual handling of high volumes of hot solvent. The software allows the analysts to create their own methods adjusted to their samples. Up to 9 fractions can be obtained automatically, and it is possible to check the fractionation process thanks to an interactive software.

Experimental

The main steps of fractionation are performed automatically following the selected method parameters:

- Dissolution of the sample at high temperature.

- Column loading with the sample at high temperature.

- Crystallization step following a selected temperature ramp.

- Elution and fractions collection pumping solvent at selected isothermal steps.

To perform a fractionation the user just needs to place a dry sample in a vessel, select the method and start the process. The vessel will be filled with solvent for dissolution and fractionation will take place according to the TREF technique. The fractions are collected in 1 or 2 liter bottles. Once the fractionation is finished, the equipment is cleaned and ready to start a new fractionation.

The implementation of an infrared detector facilitates the fractionation comprehension as it gives a reading of the concentration that is coming out of the column for each fraction so the analyst can modify the fractionation methods according to his needs. Fractionation using subambient temperatures can be used without the need of liquid coolants.

Conclusions

Fractionation of polyolefins has always been a difficult and physically demanding task due to the manual manipulation of large volumes of hot solvent.

New complex polymers require a support for the fractionation to be performed properly.

A new column-based fractionation equipment has been developed to enable the fractionation of large amounts of sample according to its chemical composition in a completely automatic way.

Currently, fractionation takes place in TREF mode, but other techniques of fractionation such as thermal gradient interaction chromatography (TGIC), molar mass, and solvent gradient interaction chromatography (SGIC) will be implemented soon.