June 2014

By A. Ortín Polymer Char, Valencia, Spain.

A higher standard in GPC/SEC analysis for polyolefins is achieved with Infrared detection, thanks to its higher sensitivity and its ability to provide Chemical Composition results that complement the Molecular Weight Distribution analysis.

Introduction

Polyolefin (PO) is the largest volume industrial polymer in the world used for making a wide range of commercial products that touch nearly every aspect of our daily lives, such as automobile parts, pipes, packaging films, household bottles, baby diapers and so on.

Polyolefin products derive their wide range of end-use properties from their semi-crystalline structure. The ability of incorporating comonomers in PE and PP makes it possible to control the polymer crystallinity, and thus control the rigidity and flexibility of polyolefin products. The controlling factor also depends to a great extent on the co-monomer variations across the Molecular Weight Distribution (MWD). In today’s competitive marketplace, products are targeted to specific applications by tailoring both molecular weight distribution and comonomer incorporation. This requires a reliable and fast analytical tool for studying comonomer incorporation, or chemical composition, along the MWD in all kinds of polyolefins.

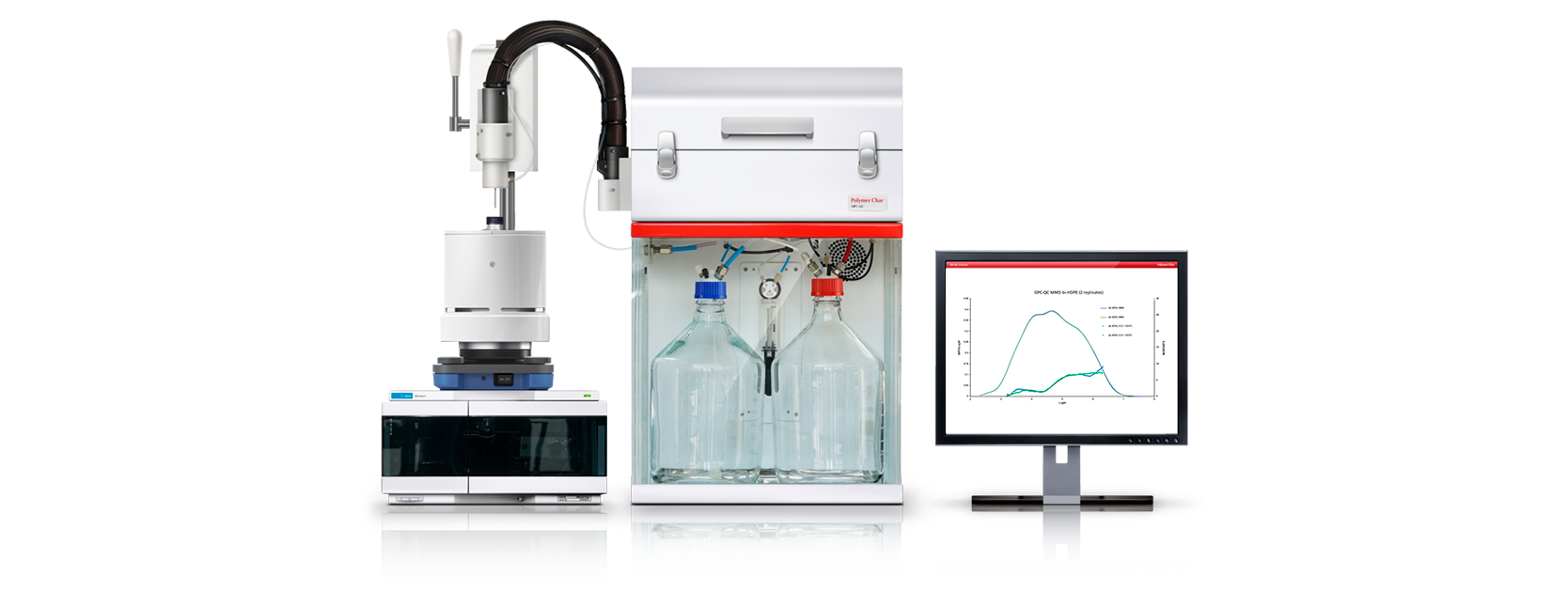

The high-temperature GPC-IR by Polymer Char is a compact and fully automated GPC/SEC instrument that has set the new standard in gel permeation chromatography for polyolefins, and has increasingly become the preferred choice in the industry.

Optimum Detection Scheme

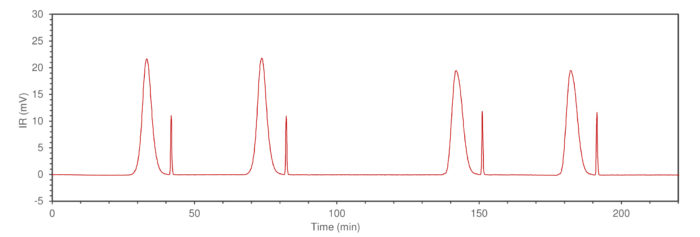

The IR detector has been shown to be the most appropriate detector for gel permeation chromatography of polyolefins. Flow rate, temperature and pressure variations have little influence on the IR absorbance, so an outstanding baseline stability is delivered by this detector (Figure 1). In addition, IR shows no injection peaks, and the chromatograms are easily integrated resulting in reliable and precise molar mass averages.

Figure 1. Sequential injections of SRM 1475 linear polyethylene (x2) and SRM 1476 branched polyethylene (x2) at 150ºC in 1,2,4-trichlorobenzene, injection volume 200µL, concentration 0,9mg/mL. A low molar mass hydrocarbon is added to every injection as flow rate marker

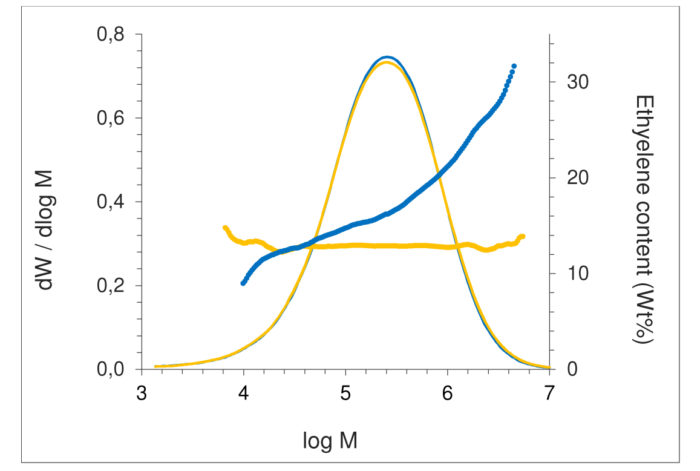

Even though its performance as concentration detector is unparalleled, what makes the IR detector unique for this application is the new dimension it provides without any analytical complexity. The sample absorbance at several IR bands is acquired as the polymer traverses the flow-through cell. It is thus possible to investigate chemical composition along the molecular weight distribution for each material analyzed. When the GPC analysis is performed with an IR detector, a wealth of useful information is obtained for catalyst development, product control or technical service support (Figure 2).

Figure 2. Analysis of two ethylene-propylene copolymers with similar molecular weight distributions but distinct ethylene distributions, as seen with IR detection.

The simple hardware setup makes IR detectors very rugged, they can withstand high pressures and need no equilibration time. The detector signal is stable even before the samples are ready for injection or the columns are equilibrated.

For high-level triple detector capability, the IR detector perfectly complements the instrument’s integrated full bridge viscometer and multiple-angle laser light scattering (MALS Wyatt Heleos II), allowing a deeper insight into the molecular architecture and the study of short chain branching, long chain branching, and absolute molar mass of homopolymers and copolymers.

Sample Care and Safety through Automation

A major innovation that is having a tremendous impact in the laboratories’ workflow is given by GPC-IR’s full automation of sample preparation, not requiring any external device nor manual work. Once the analysis is started under computer control, the instrument fills the vials by means of an integrated syringe pump. Nitrogen is directed into the vial through an intelligent valve system in order to purge the vial’s internal atmosphere, preventing oxidative degradation.

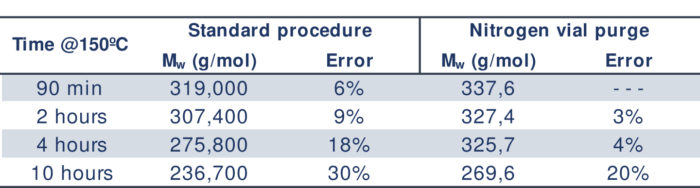

Table 1 shows the benefit of the automated nitrogen purge applied in GPC-IR and the negative effect of excessive heating.

Table 1. Effect of degradation of higher molar mass chains due to the excessive exposure to high temperature, and benefit of vials nitrogen purge. Polypropylene in 1,2,4-Trichlorobenzene

GPC-IR is the only GPC instrument that allows accurate control of the dissolution time for each vial to be analyzed. As soon as it is fully dissolved, the polymer is injected without any additional exposure to high temperature.

A durable filtration system is also incorporated in the instrument. The filter is rinsed in back-flush with clean, hot solvent after every injection. This fact, together with its optimized design, allows for very long continuous operation before replacement.

Conclusions

With the introduction of GPC-IR, a higher standard has been set for the analysis of polyolefins by Gel Permeation Chromatography technique. It has been proven that optimum detection is achieved through IR, given its stability and sensitivity while providing chemical composition information along the molecular weight distribution.