CEF

Crystallization Elution Fractionation

CEF is a fully-automated instrument for Chemical Composition Distribution analysis of polyolefins

Crystallization Elution Fractionation

CEF is a fully-automated instrument for Chemical Composition Distribution analysis of polyolefins

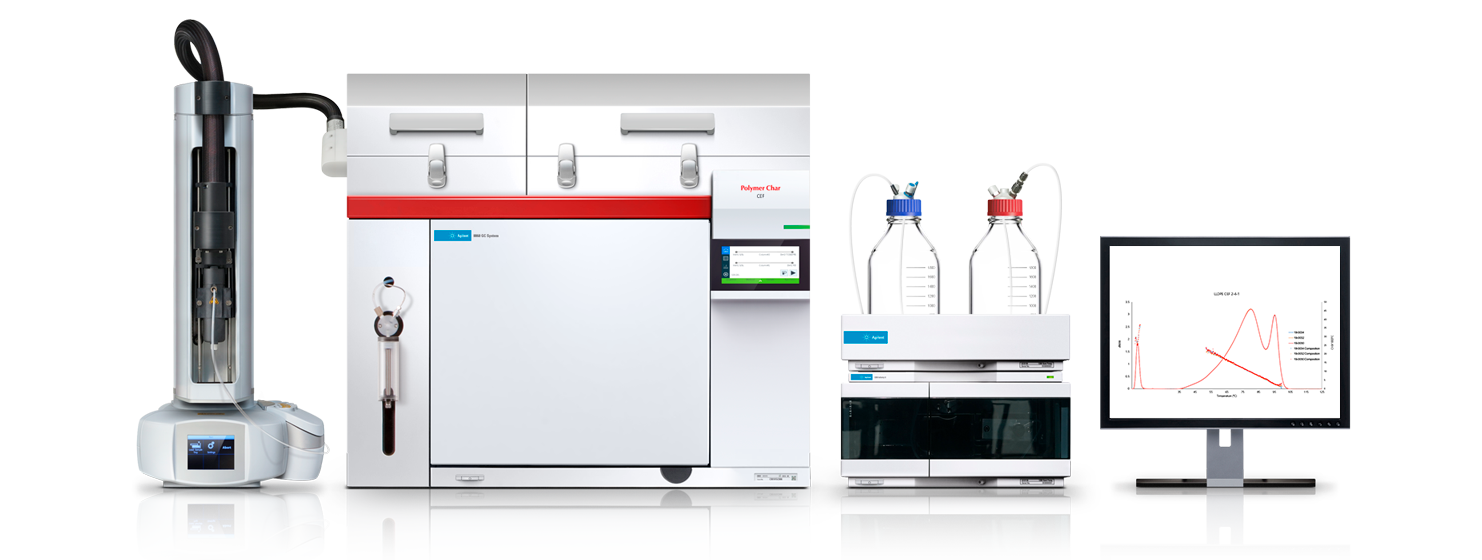

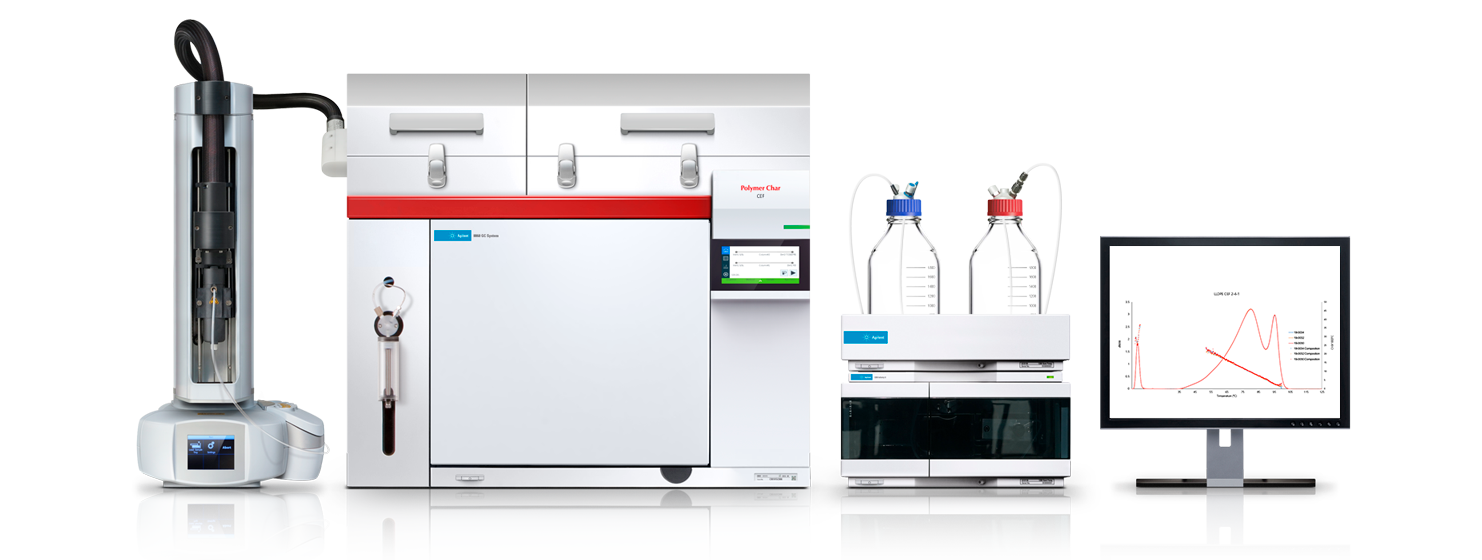

Crystallization Elution Fractionation (CEF) is a new approach for measuring Chemical Composition Distribution (CCD) in polyolefins by combining Crystallization Analysis Fractionation (CRYSTAF) and Temperature Rising Elution Fractionation (TREF) separation mechanisms. The instrument includes the capability of performing TREF and Thermal Gradient Interaction Chromatography (TGIC) techniques.

CEF is a simple and reliable apparatus, requiring an injection valve, a packed column, a pump, and an IR detector. The autosampler, attached to the CEF oven, takes care of sample dissolution in vials of 10 or 20 mL. The instrument can analyze up to 42 samples a day with disposable glass vials. The virtual instrumentation software controls the full process; therefore, no manpower is required. At the end of each sample analysis, the lines and the column are rinsed and CEF will continue with the analysis of the next sample in the queue.

The concentration of the sample is measured by an Infrared (IR) detector (IR4, IR5, or the latest IR6 from Polymer Char), which also provides information about its comonomer content. More information on molar mass composition interdependence can also be obtained by adding a Viscometer detector. Optionally, the TREF column can be replaced by a TGIC column in order to separate by adsorption and reach the composition range of elastomer resins. The latest IR6 is also available, which offers the same superior performance as the IR5 but with the additional capability of measuring carbonyls group in the band of 1740 cm-1.

CEF is a technique developed and patented by Polymer Char.

· One instrument, three techniques: fully-automated CEF, TREF and TGIC* techniques (CCD measurement)

· No manpower required

· No manual handling of solvents

· Low solvent consumption

· Automated rinsing at the end of the analysis

· Subambient operation (down to -15ºC) for low crystallinity samples

· Possibility of incorporating a Viscometer detector

· 42 samples can be analyzed sequentially and automatically with an analysis time as short as 30 minutes per sample for a high-throughput analysis or as long as desired for a high-resolution analysis

· Interchangeable Infrared Detectors; IR4, IR5 for outstanding sensitivity in concentration and composition, or the latest IR6

· Possibility of adding a Viscometer detector

· Excellent reproducibility

· Possibility of performing TGIC* by exchanging the column

· Dissolution time can be programmed individually for each vial, therefore, thermal degradation is minimized

· A gentle shaking movement inside of the autosampler oven helps in speeding up the dissolution process without the shear stress of magnetic stirring bars

· Oxygen can be removed from the vial by the automated nitrogen vials-purge system, in order to prevent oxidation of the dissolving polymer molecules

The following are the detectors available for CEF:

The IR4 is the standard Detector integrated by default in all the Polymer Char analytical instruments. IR4 is a dual-wavelength infrared detector, which uses the principle of infrared absorption spectroscopy to measure the concentration and composition in polyolefins.

The IR5 is a high sensitivity infrared detector designed for measuring concentration and short-chain branching with superb stability. It incorporates interference filters at five different wavelengths.

The IR6 Detector is the latest IR Detector developed by Polymer Char, with the same performance and sensitivity than IR5 Detector and the additional capability of measuring carbonyls group in the band of 1740 cm-1. We recommend the IR6 Detectors for users willing to analyze polyolefin type EVA, EBA, and others with carbonyls group present in the IR band above.

Polymer Char offers a highly sensitive Four-Capillary Differential Bridge Viscometer or a Two-Capillary Relative Viscometer. Both options are an ideal complement to the infrared detection systems implemented in many of the polyolefin characterization instruments, such as GPC-IR or CEF. Viscometer configuration is optimized to achieve a better performance in each technique.

The CEF Software is specifically designed for controlling and automating the process; no manpower is required. The software deals with the whole process, including samples preparation with the vials filling and dissolution.

Up to 42 samples can be managed by the software to be run with no supervision. As each sample from the run-queue is injected and eluted, results can already be accessed from the calculations database to be reviewed, overlaid with others, to generate a report, export to Excel, even though the instrument is still running.

The manual mode in the software is also incorporated as in the rest of Polymer Char’s instruments, so the autosampler, dispenser, ovens, pump, etc.; can be directly operated by the user by means of a powerful Virtual Instrumentation interface.

A wide range of the CEF analytical process conditions are available to the user, to allow the needed flexibility for both routine analysis and research jobs, as well as to allow running a standard TREF analysis.

To request a demo, please contact us

Read more about One Software

CEF (Crystallization Elution Fractionation) instrument is a simple and reliable high-throughput analyzer performing a new approach to measure the Chemical Composition Distribution (CCD) in polyolefins by combining CRYSTAF and TREF separation mechanisms. CEF is of special interest for high speed analysis.

CEF instrument can perform TREF method directly, without any change in the configuration of the instrument. CEF instrument can also perform TGIC method by acquiring the corresponding license from Polymer Char (TGIC is a patented technique by The Dow Chemical Company).

CEF is an analytical instrument intended to obtain the chemical composition distribution curve, but it doesn’t provide any physical fraction. For this purpose, please read about PREP mc2.

Up to 42 vials can be handled by the CEF autosampler, and they can be dissolved and analyzed with no supervision required. Each sample can be analyzed with different conditions, so the total time will depend on the analysis method selected for each sample. Analysis method time may vary between 30 min up to several hours, obtaining a fair resolution when analyzing 50 samples per day.

The standard amount used in CEF analysis is 32mg per sample in 8 mL, therefore the instrument can be used both for research and also for quality control.

1,2,4-Trichlorobenzene (TCB) and Orto-Dichlorobenzene (oDCB) are the most used solvents. To use other solvents please consult Polymer Char first.

No samples preparation is required by the user but weighing the dry samples and putting them inside of the disposable glass vials. The rest of the steps are performed by the instrument automatically: vials filling, dissolution, filtration, injection, elution, etc.

Different analysis conditions can be selected from the CEF software for each vial within the same run, therefore, different samples can be analyzed unattended and with the appropriate dissolution time, crystallization ramp, elution ramp, pump flow, etc.

Solvents don’t need to be handled at any time; the whole process is fully automated, the instrument is in charge of all the needed steps: vials filling, dissolution, filtration, injection, elution, etc.

No prefiltration step is required by using CEF instrument thanks to an in-line filter, which is integrated in the instrument as an option, connected before the CEF column. Additionally, after each injection, this filter is automatically cleaned in backflush to become ready and clean again for the next injection.

LLDPE, LDPE, HDPE, PP, E-P copolymers, multicatalyst reactor resins, and any semicrystalline polymer soluble in TCB or oDCB, giving response to C-H absorption.

CEF incorporates an infrared detector to measure the concentration of the solution which is being eluted and going out of the column. This detector can be Polymer Char's IR4, IR5, or the latest IR6, all in their integrated versions.

A capillary viscometer detector can be connected to the CEF instrument, to obtain information on composition-molar mass interdependence.

After each injection, data can already be accessed and calculated through the CEF software database. Polymer Char CEF Calculations software integrates all detectors' signals in the same package. A reporting tool is available to generate reports in Excel adapted to each user's needs.

Thank you for your interest. If you would like to receive more information or want to request a quotation please complete this form.

This site uses cookies to give you a better browsing experience. If you continue

browsing this site we understand that you accept our use of cookies.

For more information,

please visit our Cookies Policy. You can configure which

cookies you accept by ticking the next options: