Company Overview

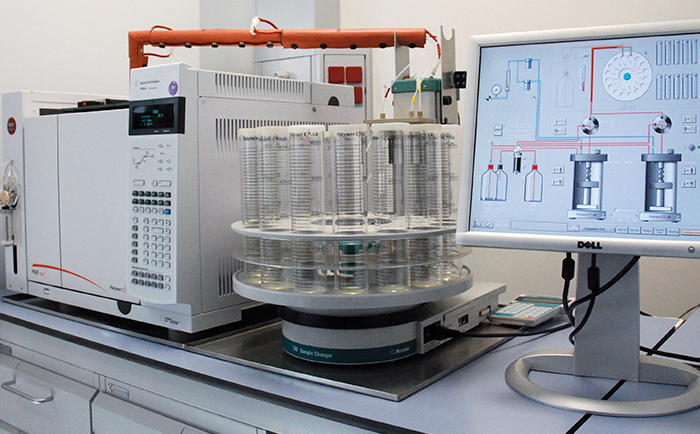

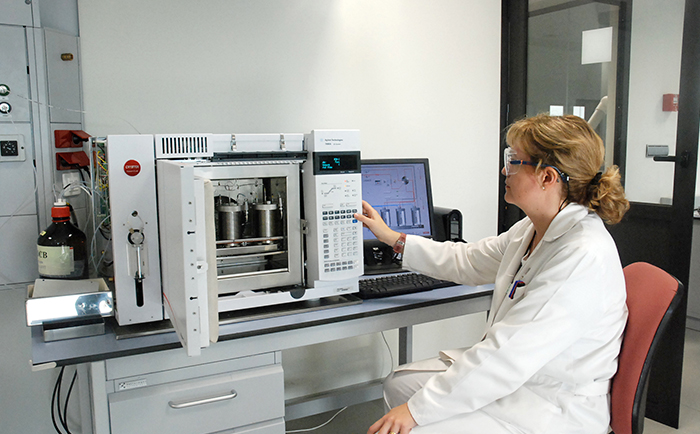

Polymer Char presents an extensive and modern range of instruments and services tailored for the structural characterization of polyolefins. Some of the technologies in the instrumentation portfolio include Gel Permeation Chromatography (GPC/SEC), Chemical Composition Distribution, Bivariate Distribution, High-Temperature HPLC, Soluble Fraction determination, Quality Control, Intrinsic Viscosity measurement, Preparative Fractionation, and Infrared Detection.

Renowned for its pioneering approach to Virtual Instrumentation Software Architecture (VISA), Polymer Char leads in instrumentation diagnostics and technical support. This advanced software, coupled with robust remote control capabilities and an unwavering commitment to customer success, positions the company at the forefront of the industry.

In collaboration with a worldwide network of partners and distributors, Polymer Char delivers, educates, and assists clients across the globe. The company offers analytical services to over 35 countries, and has instruments installed across more than 25 nations in the Americas, Europe, Africa, the Middle East, and the Asia Pacific. The industries the company serves are mainly Polymer Producers and Processors, Government and Contract Research Laboratories, as well as Universities engaged in polymer research.

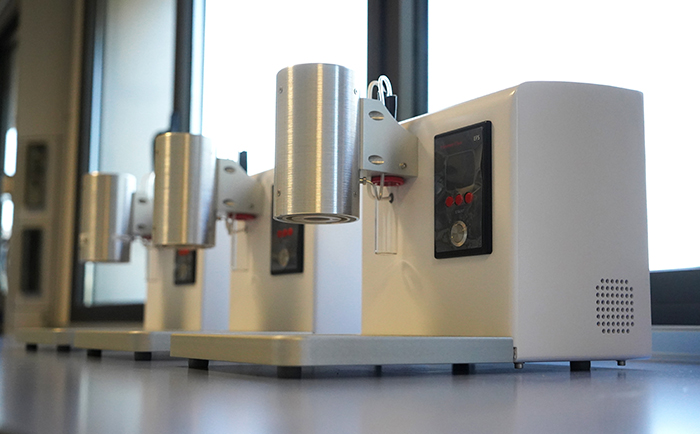

Over the past three decades, Polymer Char has played a pivotal role in advancing the majority of existing polyolefin characterization technologies, including, such as CRYSTAF, CRYSTEX, CEF, automated CFC, and TREF, GPC with IR detection, and automation of high-temperature Intrinsic Viscosity. Each new project, each new analysis, bolsters Polymer Char’s reputuation as the expert in Polyolefin Characterization.

In the realm of polyolefin analysis, Polymer Char offers an unwavering commitment to technical excellence, proficiency, and overall customer satisfaction. Our high-quality solutions and Exceptional Customer Care philosophy underscore our dedication to advancing the field. Today, Polymer Char’s contribution to the community is expanding even further and becoming more significant. The company’s progress in instruments and technology is playing a key role in advancing the production and study of sustainable materials, and ease of plastic recycling.

As you browse through the website, you will find a large set of tools, patented technologies and superb engineering to support the challenging field of polyolefin characterization.

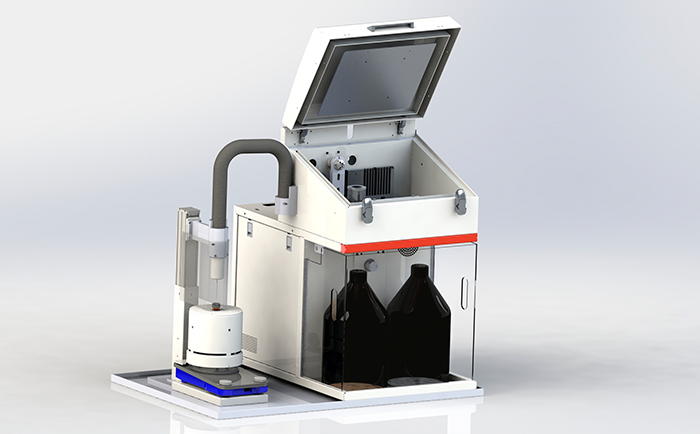

We know of the instrument complexity demanded to characterize polyolefins, and how tedious lab operations may become in this field. With a strong commitment to innovation, and working close to our customers, Polymer Char has pursued a new scenario of automation, speed, and ease of use. We have developed and patented new technologies to analyse the chemical composition distribution, like CEF, a standard in the industry that is also able to operate in TGIC mode, or the benchtop CFC and SGIC instruments. We put more resources than ever before towards developing our best high temperature GPC solution the GPC-IR®- which is also the instrument of reference in its field and will soon be coming with new detectors. We have developed a series of quality control instruments to provide fast results to better monitor products and processes. We launched the LabAid solutions to make things easier in the daily lab operations. We are continuously hiring good and talented people.

While these are just some examples of how we are energizing our business to adapt to our customers’ needs, from the corporate social responsibility perspective we are also leading a series of initiatives and projects that will ensure that our organization becomes more efficient and sustainable. We are actively involved in two highly ambitious projects which will have great environmental impact in the area of plastic recycling and in the use of greener solvents for polymer analysis.

We have also initiated an internal engagement program which includes a series of events in which all employees take part, including sponsoring sport events. We are bringing experts from various disciplines to our site to share their learnings. In 2022 we will inaugurate a new Analytical Laboratories Center next to our headquarters in Valencia. This will showcase a state-of-the-art lab and ensure there is full dedication and greater performance in our analytical services business.

Polymer Char has become a mark that represents excellence. We are well recognized by the talent and attitude of our employees, which is also extended to our official distributors.

As the company continues evolving and adapting to its customers’ and the market’s needs, the mission of perpetuating Polymer Char’s legacy lies in Javier Monrabal, currently Chief of Operation & Strategy. In 2016, Javier took on a leadership role within the company to drive it into the future with new ideas that, nonetheless, stay true to the company’s long-standing values.

Looking forward, you have our commitment that we will continue guiding our business with true dedication to our customers, a relentless effort to continuously improve our solutions, a responsible position towards the environment, and integrity and ethical principles on everything we do.

Benjamín Monrabal Bas

Founder and CEO

Dr. Benjamin Monrabal, was born in 1946 in Valencia, Spain. He received a Chemical Engineering degree from the Instituto Químico de Sarriá in Barcelona; and a PhD in Polymer Chemistry from the Virginia Polytechnic Institute, U.S.A.

From 1970 until 1992 Dr. Monrabal worked at The Dow Chemical Company, where he was appointed Associate Scientist for his technical contributions to the polyolefin LDPE and LLDPE processes. While he was the manager of a central lab at Dow in The Netherlands he invented and patented the CRYSTAF analytical technique, which was a breakthrough in the optimization and development of LLDPE resins.

In 1992, Dr. Monrabal founded Polymer Char with the mission of developing a commercial and fully automated CRYSTAF instrument. Most significant at that time was building a new company into a framework centered around innovation and customer satisfaction. To this day, the involvement of talented and responsible employees who identify with the company’s values is one of the major contributors to Polymer Char’s success.

During his career, and complementary to his work as General Manager and R&D Director of Polymer Char, Dr. Monrabal has contributed to the development of various polyolefin characterization techniques. He is the inventor of the CEF technique – now a patented and standard tool in the PO industry – and has led a comprehensive new approach in the analysis of polyolefins by high-temperature GPC. He has also contributed to the understanding of the new Interaction Chromatography techniques.

Dr. Monrabal has authored many publications on Polyolefin Characterization, and is in close collaboration with various Universities, Research Institutes, and leading Polymer companies in the development of new methodologies for extensive characterization of Polyolefins. He has been a member of the Editorial Boards of the International Journal of Polymer Analysis and Characterization, and Journal of Liquid Chromatography. Currently, he is a member of the ICPC (International Conference on Polyolefins Characterization) scientific committee.

The establishment of Polymer Char centered around fully developing a commercial instrument to perform the CRYSTAF technique, from the presentation of a prototype at a tradeshow to selling the first unit to a South Korean company.

After the launch of CRYSTAF, a commercially automated TREF followed and other technologies started being developed as the result of close collaboration with petrochemical leaders in the industry.

After continuously providing consulting and services worldwide, Polymer Char consolidates its Laboratory Analytical Services business unit for plastic testing and analysis. The technology of the CEF technique is patented.

The ICPC Conference is founded and the first edition held with widespread acceptance. Two ground-breaking techniques in the field of GPC for polyolefins are launched setting a new standard for high-temperature analysis in the industry. The corporate brand is elevated with a brand new building for headquarters and an image revamp.

The company's highest R&D peak up to date takes place as seven different instruments are developed and introduced to the market within this timeframe, including a full line of QC instruments.

As the product portfolio comes full circle with the launch of a line of accessories for the laboratory, the company is now venturing into new markets with R&D dedicated to other detection systems and techniques capable of expanding its range of analysis to more plastics other than polyolefins.

This site uses cookies to give you a better browsing experience. If you continue

browsing this site we understand that you accept our use of cookies.

For more information,

please visit our Cookies Policy. You can configure which

cookies you accept by ticking the next options: