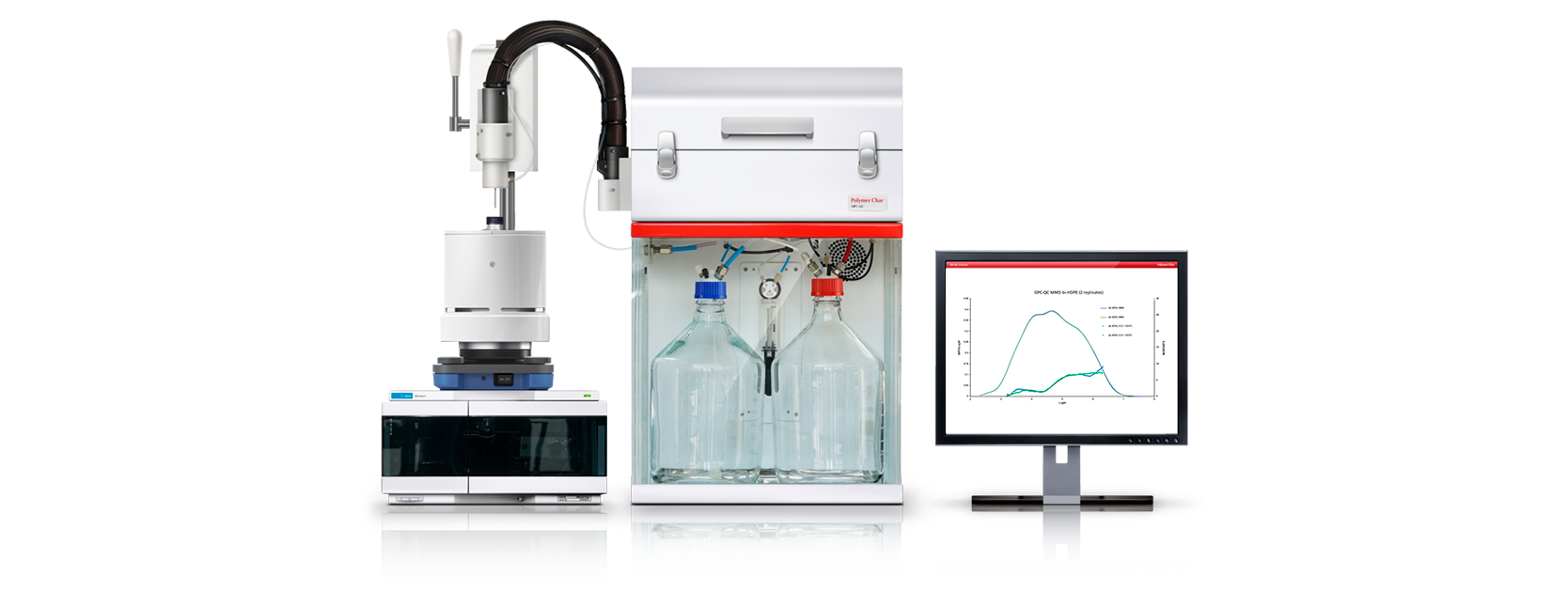

GPC-IR® Features

Click on each feature to display

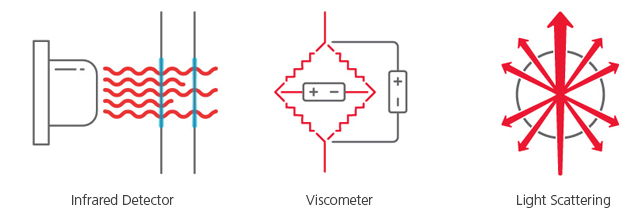

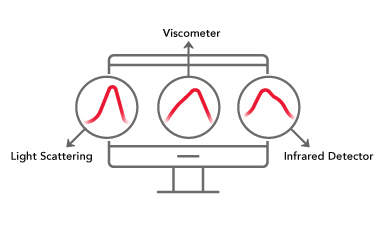

The full characterization of polyethylene and polypropylene polymers requires a high-temperature GPC/SEC analysis to be made with specific detectors. GPC-IR® incorporates infrared detectors, demonstrated to be the best option for this kind of polymers. The three models available, IR4, IR5, and IR6 can measure both molecular weight and chemical composition (SCB/1000TC). The triple detector configuration is completed with a four-capillary bridge built-in Viscometer (developed by Polymer Char), and a multi-angle Light Scattering detector.

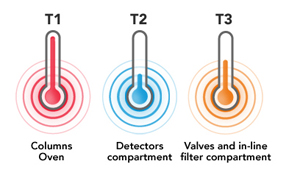

GPC/SEC columns are fragile and need to be isolated from temperature changes. For this purpose, GPC-IR® was designed with a dedicated and precise (0.01ºC) oven to hold only the columns. The columns can remain at high temperature even when the detectors and injector oven need to be cooled down for maintenance tasks. The temperature can be controlled independently for each of the compartments, thus optimizing the performance and lifespan of the instrument.

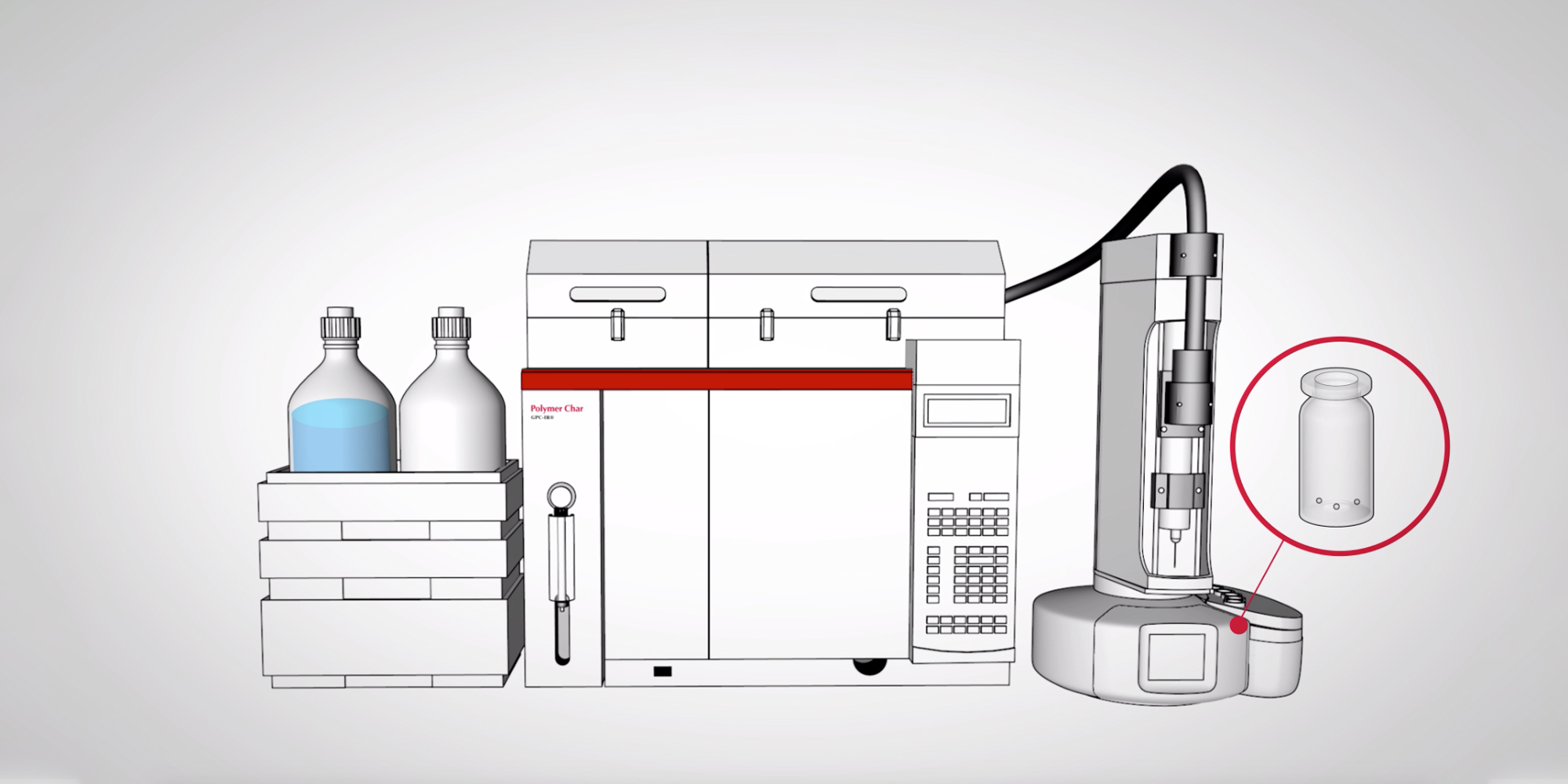

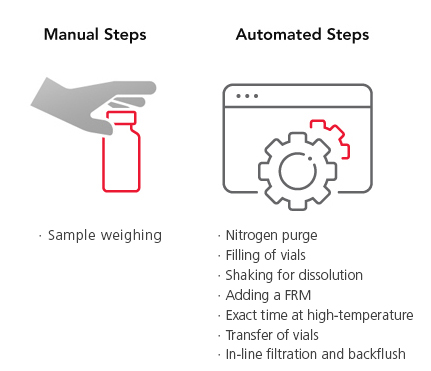

With an autosampler with a 42-sample capacity, every step is automated by GPC-IR®, including filling of vials with solvent, dissolution of the sample by shaking, injection into the columns, and in-line filtration with backflush cleaning. The only manual requirements are weighing the sample and starting the software. Neither vial transfer nor manual handling of solvents will be needed throughout the entire process.

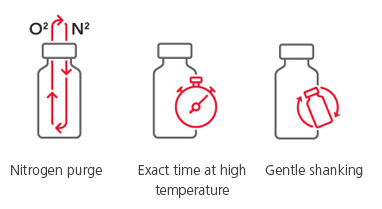

Sample degradation has been present historically in SEC analyses due to long dissolution times, the use of stirrers, and the presence of oxygen in the vials. However, when using GPC-IR®, sample degradation is significantly minimized thanks to keeping each sample at high temperature only for the exact time required for dissolution, the use of gentle shaking rather than magnet stirring, and a nitrogen purge to remove the oxygen in each vial. Furthermore, the dissolution time can now be shortened due to an efficient and homogeneous heat transfer to the vials.

The GPC One® Calculations Software was developed in collaboration with the leaders in the industry in order to meet the needs of both, highly experienced users and new ones as well. All of the detectors’ signals are integrated to become the most comprehensive calculations software package available in the market. The GPC One® Software is complemented with built-in customizable reports and statistical quality control tools.

GPC-IR® is designed to easily access each component and facilitate the maintenance tasks when needed.

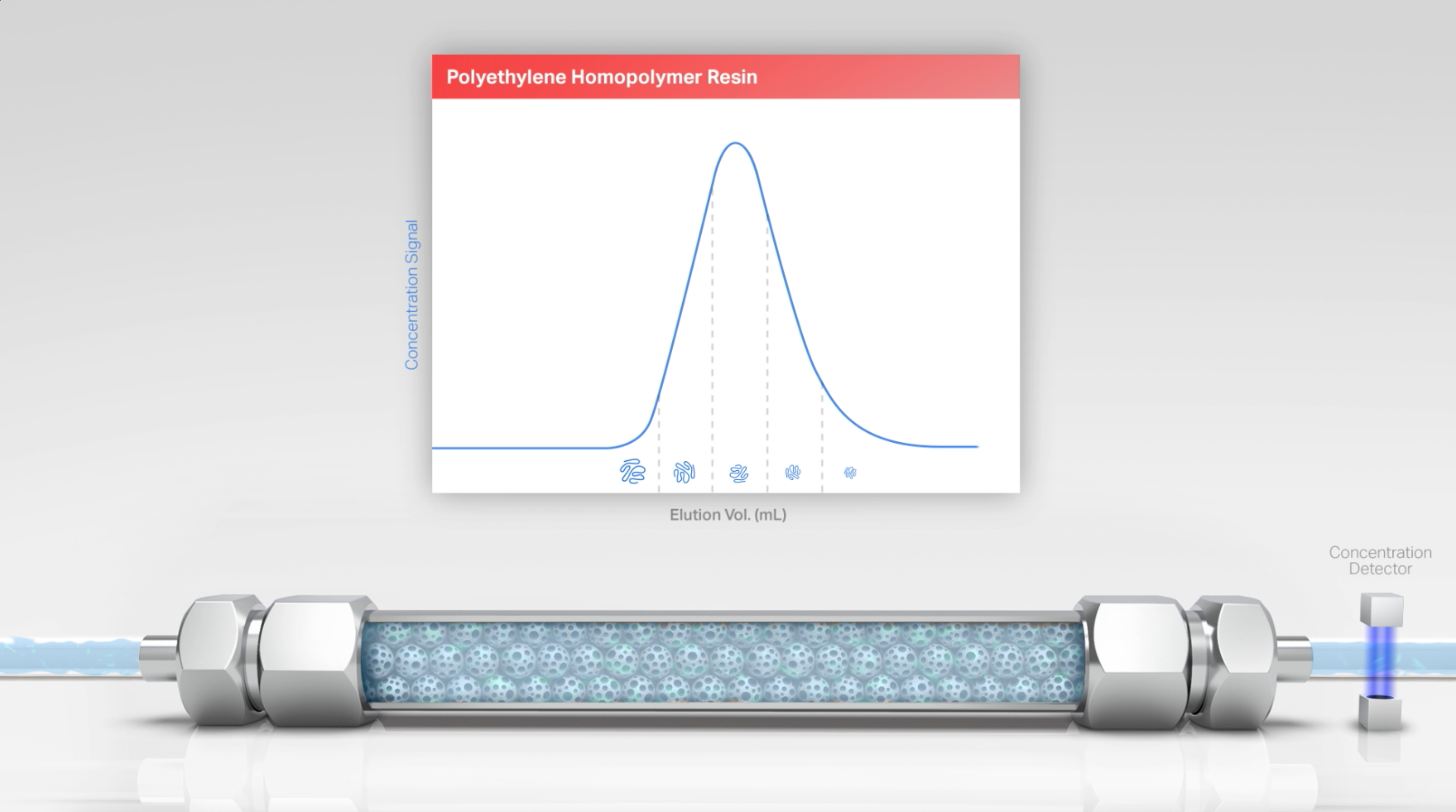

GPC/SEC Technique Explained

The Gel Permeation Chromatography technique is a useful tool for revealing much about a resin's microstructure. This video explains the separation process as well as the implications of using of different types of detectors.

GPC-IR® Detectors

The following are the detectors available for GPC-IR®:

Infrared Detector IR4

IR4 is the standard detector integrated by default in all Polymer Char analytical instruments. IR4 is a dual-wavelength infrared detector, which uses the principle of infrared absorption spectroscopy to measure the concentration and composition in polyolefins.

Infrared Detector IR5

IR5 is a high-sensitivity infrared detector designed for measuring concentration and short-chain branching with superb stability. It incorporates interference filters at five different wavelengths.

Infrared Detector IR6

IR6 is the latest infrared detector developed by Polymer Char. It has the same performance and sensitivity as the IR5 detector and the additional capability of measuring carbonyl group in the band of 1740 cm-1. The IR6 detector is recommended for users that want to analyze EVA, EBA, and other polyolefins which have carbonyl group present in the 1740 cm-1 band.

Viscometer

A highly sensitive four-capillary Differential Bridge Viscometer can be included in the GPC-IR configuration to provide Intrinsic Viscosity data. A viscometer detector also allows for the analysis of Long-chain Branching (LCB), and the appliation of Universal Calibration. The viscometer configuration is optimized to achieve the best performance in GPC/SEC technique.

Light Scattering

With the use of a Light Scattering detector in GPC, absolute Molar Mass and LCB results are obtained. The GPC-IR® design can integrate an external high-temperature Multi-angle Light Scattering detector (MALS). The GPC One software integrates the MALS signals and processes them together with the other detectors' signals.

GPC-IR® Video

GPC-IR® Software

The high-temperature GPC / SEC technique requires complex data processing as multi-detection methods become widespread. Processing all the detectors signals in a single software environment and in a uniform manner is a wish for most users. Tracking the quality of the results given by the instrument is a critical aspect to quickly validate or reject a given analysis. In many cases, it is also necessary to adapt the results and to process the unique needs of each company.

Polymer Char’s One Software platform has been developed to achieve all these goals, including an updated data acquisition hardware with multiple computer communication interfaces. All the detectors signals are acquired and processed in a single environment in an easy and efficient way, allowing the analysts to have customized reports without going through multiple dedicated software tools for each task.

A Statistical Quality Control database has been integrated into the software packages to help track instrument performance. With this new approach, the performance of all the elements in the GPC-IR® system is monitored in a simple and efficient way with control charts. This ensures the reliability of the results by alerting of malfunctioning parts and other sources of error, like calibration drifts or detector signal to noise ratio degradation.

It is also possible to customize the data processing and calibration procedures as well as the generated reports. Unique protocols that many companies need to follow for implementing specific data corrections or established calculation methods are integrated seamlessly into the standard software.

To request a demo, please contact us

Read more about One Software

GPC-IR® FAQs

The purpose of a Gel Permeation Chromatography or Size Exclusion Chromatography analysis is the determination of the Molecular Weight Distribution of the sample. In the case of polyolefins, the GPC/SEC technique has always been considered a demanding task due to the high temperature required for dissolution, and the use of multi-detector methods.

Molecular Weight Distribution and Long-chain Branching is measured much the same by all Gel Permeation Chromatography systems using a triple detector configuration (DRI or IR, Viscometer, and MALS detectors). However, what is unique about GPC-IR is that its Infrared detector can measure Short-chain Branching and functional groups in polyolefin copolymers along the molecular weight distribution. Another significant feature that sets Polymer Char’s GPC system apart from others is that it automates the whole sample preparation process so, unlike with other high-temperature GPC instruments, the user never manipulates solvents manually when using GPC-IR.

The GPC-IR autosampler can handle up to 42 vials. The total analysis time will depend on the number of columns, detectors, and injections done per vial. The analysis time of each injection can be programmed individually, but a standard SEC analysis with 3 columns typically lasts around 55 min. The total analysis time should be NxA, N being the total number of injections, and A the Analysis time. Only the dissolution time of the first sample should be added to the total time, as the instrument starts dissolving the next sample whilst the first one is being analyzed.

To learn more about analysis time, sample dissolution, solvent consumption, and other practical considerations, click the link below:

16mg of sample are used as a standard for preparing a 2mg/mL solution in the autosampler vial.

1,2,4-Trichlorobenzene (TCB) and Orto-Dichlorobenzene (oDCB) are the typical solvents used with GPC-IR. To use other solvents please consult Polymer Char first.

The GPC-IR instrument is focused on high-temperature applications (maximum temperature of the column oven: 250ºC, solvent, and columns dependant).

The only manual tasks required are weighing the dry samples, putting them inside disposable glass vials, and placing those vials in the autosampler tray. The rest of the steps are performed by the instrument automatically: filling the vials with solvent, sample dissolution, filtration, injection, as well as rinsing the valves and lines.

Different dissolution times can be selected in the GPC-IR Software for each vial in the run-queue within the same run; therefore, samples with different preparation requirements can be analyzed at once.

You will not need to handle solvents manually at any time as the whole process is automated: vials filling, dissolution, filtration, injection, etc.

For a completely automated solvent handling process, Polymer Char also offers a Solvent Handling Trolley to transfer fresh and waste solvent from the solvent station to the instruments.

When using a GPC-IR instrument, no pre-filtration step is required thanks to an in-line filter integrated in the instrument. After each analysis, this filter is automatically washed in backflush, so it is clean and ready for the next injection.

You do not need to transfer the sample between vials. The same vial is used throughout the whole process.

GPC-IR is specially designed for Polyolefin analysis at high temperature with chlorinated solvents. The GPC-IR with the standard IR detector can be used to analyze all polymers soluble in chlorinated solvents (TCB, o-DCB, perchloroethylene), which have C-H bonds in the backbone. When adapting an external Refractive Index or an ELSD detector, it can also be used with all types of synthetic polymers.

Additional detectors can be easily connected to the GPC-IR instrument, such as viscometer, Light Scattering, external Refractive Index or ELSD detectors.

The GPC-IR injection system has been designed in an innovative way that allows up to 3 injections per vial with no dilution of the sample's concentration. Therefore, the reproducibility among the injections is outstanding

The columns stay isolated in a dedicated and high-precision oven, to protect them from any temperature changes that may happen during instrument maintenance.

The columns can be kept at high temperature while performing maintenance tasks in the detectors, filters, or injection loop because they are located in a dedicated oven, where the temperature can be operated independently from the rest of elements.

After each injection, the data can be accessed and processed through the GPC-IR Software database. Polymer Char’s GPC One is currently the most comprehensive GPC Calculations Software package, because it integrates all the detectors signals and can be customized to include in-house data-processing procedures. A reporting tool has also been developed to generate Excel reports adapted to each user's needs.

Polymer Char's Infrared detectors (IR4, IR5, IR6) provide SCB information, and each one is recommended depending on the application. The IR4 has a sensor sensitive to methyls and carbonyls groups for short-chain branching quantification across the molecular weight distribution. The highly sensitive IR5 is recommended when low levels of SCB need to be detected. Finally, the new IR6 detector provides outstanding sensitivity and baseline stability in concentration, composition and carbonyls signals even with low concentration values.

LCB results can be obtained by just using the standard capillary viscometer by comparison of the branched sample intrinsic viscosity with that of a linear reference at every molar mass slice. More accurate results are produced when using both MALS and viscometer detectors. SCB information is very useful to correct LCB calculations.

The capacity of the vials is 10mL and, on standard conditions, they're filled with 8mL, from which up to three injections can be done. The minimum volume required is 6mL, in this case the number of injections per vial is reduced.

The standard injection loop is 200uL but it can vary according to the user's needs.

Preventive maintenance is recommended once a year. For more information, click on the link below.

You can request a quotation via the Contact Form or by sending us an email to sales@polymerchar.com

Request More Information about GPC-IR®

Thank you for your interest. If you would like to receive more information or want to request a quotation please complete this form.

This site uses cookies to give you a better browsing experience. If you continue

browsing this site we understand that you accept our use of cookies.

For more information,

please visit our Cookies Policy. You can configure which

cookies you accept by ticking the next options: