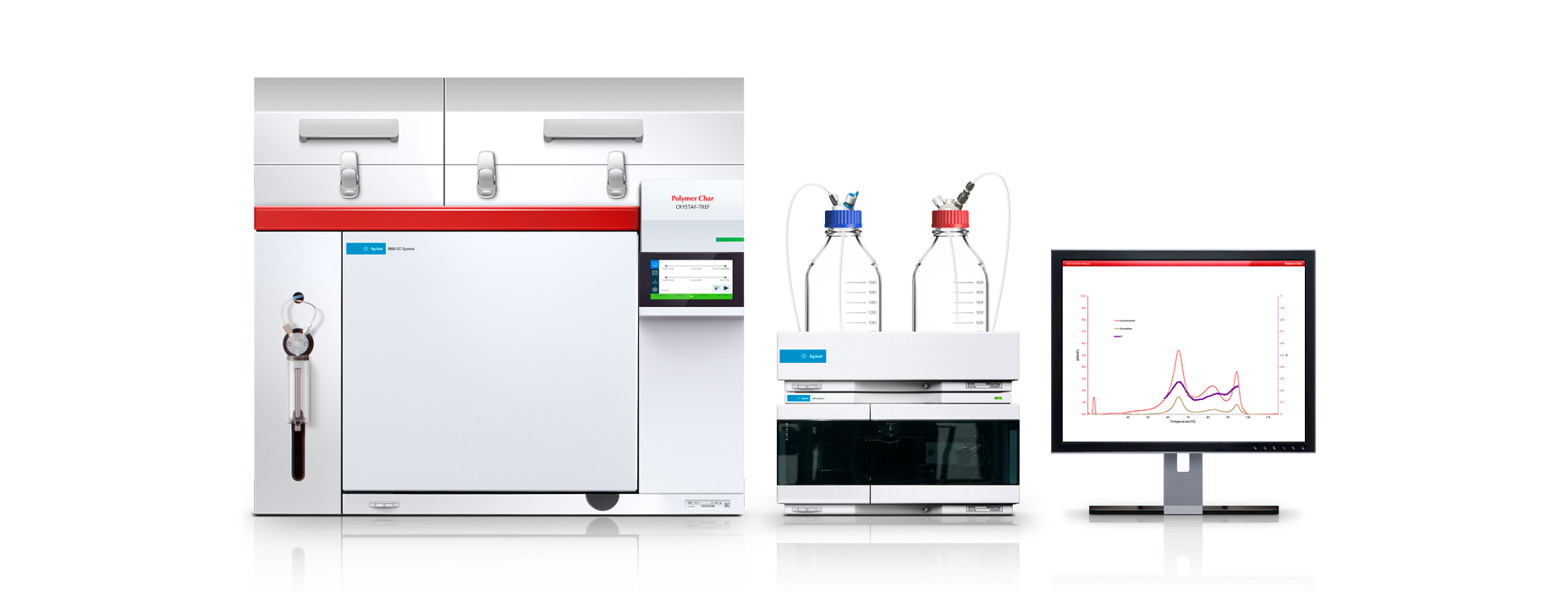

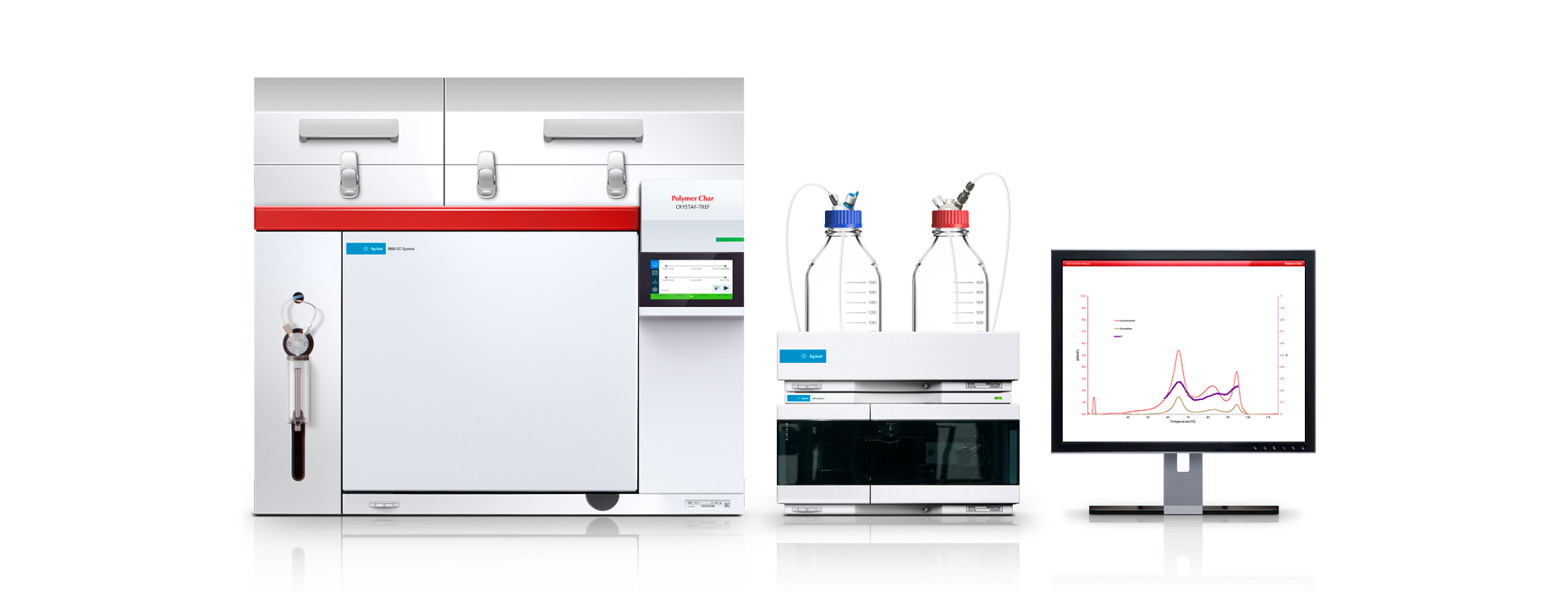

CRYSTAF-TREF

The analytical power of CRYSTAF and TREF together in a single instrument for a full Chemical Composition Distribution characterization.

The analytical power of CRYSTAF and TREF together in a single instrument for a full Chemical Composition Distribution characterization.

Both the Crystallization Analysis Fractionation (CRYSTAF) and Temperature Rising Elution Fractionation (TREF) techniques are intended to measure the Chemical Composition Distribution in Polyolefins. CRYSTAF analyzes the Chemical Composition Distribution (CCD) in the crystallization cycle and TREF in the dissolution cycle.

The analysis of complex PP-PE combinations has been shown to require both TREF and CRYSTAF to unequivocally characterize unknown samples, due to the differences in the undercooling between both resins. Such a case is the analysis of samples containing both HDPE and Ethylene-Propylene copolymer (EP) for instance.

In TREF the two components will not be well resolved but CRYSTAF will be capable of getting a very good separation. An opposite case is the analysis of samples containing both HDPE and Ziegler type PP homopolymer, which will be separated better with TREF than with CRYSTAF.

Therefore, the CRYSTAF-TREF instrument is a very convenient option when needing to analyze the CCD in Polyolefins, since either CRYSTAF or TREF techniques can be performed just by changing the configuration of the equipment.

· Benchtop instrument with the possibility of performing CRYSTAF or TREF techniques.

· Fully-automated processes, from the sample preparation up to the final cleaning. No manpower and no solvents handling.

· Possibility of analyzing up to 5 samples with no supervision required.

· Low solvent consumption.

· Infrared Detector IR4 incorporated, with the possibility of adding a composition sensor for methyls or carbonyls measurement.

· Possibility of adding a Viscometer detector in TREF mode.

· Possibility of sub-ambient capability (down to -15ºC) for low crystallinity samples.

· Virtual Instrumentation software with whole control of the instrument process, storage of all the detectors signals and monitoring of the sensors system.

· Possibility of remote control capability for fast diagnosis and support from Polymer Char Service Center.

The following are the detectors available for CRYSTAF:

The IR4 is the standard Detector integrated by default in all the Polymer Char analytical instruments. IR4 is a dual-wavelength infrared detector, which uses the principle of infrared absorption spectroscopy to measure the concentration and composition in polyolefins.

Polymer Char offers a highly sensitive Four-Capillary Differential Bridge Viscometer or a Two-Capillary Relative Viscometer. Both options are an ideal complement to the infrared detection systems implemented in many of the polyolefin characterization instruments, such as GPC-IR or CEF. Viscometer configuration is optimized to achieve a better performance in each technique.

Both CRYSTAF and TREF Software packages are available in the instrument to run the corresponding technique depending on the instrument mode configuration.

The Software is specifically programmed to run samples by CRYSTAF or TREF with no supervision required, with the possibility of selecting pre-saved method conditions to run routine samples and also of modifying any analysis condition such as temperatures, volume, rates or time; to better adapt them to the specific characterization job.

In addition, manual mode allows the user to operate directly the whole hardware of the instrument to perform specific research experiments or to facilitate a maintenance task. It is also a powerful diagnosis tool, together with the option of being operated remotely by the Polymer Char service engineers.

A data processing software has been incorporated, together with useful databases, to access all the previously analyzed samples, and review, overlay or generate printed or exported reports.

To request a demo, please contact us

Complex PP/PE copolymers require both. For example, TREF alone can’t distinguish a combination of HDPE and EP copolymer, while CRYSTAF alone can’t analyze a combination of HDPE and

Ziegler-type PP homopolymer. Polyolefins are getting more complicated all the time.

CRYSTAF (Crystallization Analysis Fractionation) and TREF (Temperature Rising Elution Fractionation) techniques were developed to obtain the Chemical Composition Distribution curves; CRYSTAF during the crystallization and TREF during the elution cycle. Therefore, at the end of a CRYSTAF or TREF run, a distribution in concentration versus temperature of crystallization or elution is obtained.

CRYSTAF obtains the CCD curve during the crystallization step, and TREF does need an additional temperature cycle called elution to obtain the same results.

TREF obtains the CCD curve directly and in a continuous way, meanwhile the CRYSTAF technique does so in a discontinuous way: A series of data points from the cumulative composition distribution curve are actually measured and used to obtain the differential distribution by means of a smoothing splines fitting algorithm.

CRYSTAF obtains the CCD curve during the crystallization process, and TREF does need an extra temperature cycle called elution to obtain the same results. The results obtained with both techniques are very similar but when expressed in temperature scale there exists a shift to lower temperatures in CRYSTAF due to undercooling effects.

For most of the polyolefins, results obtained from CRYSTAF or by TREF will be equivalent, and therefore only one of the techniques is enough in most cases. However, for some specific kind of polyolefin, separation might be better achieved by CRYSTAF or by TREF due to the different behavior of the components in the crystallization or elution process. In this sense, if having both techniques available, the best possible separation will be achieved for every sample.

CRYSTAF and TREF instruments hardware is very similar, and therefore both techniques can be run in the same physical equipment by changing the instrument internal mode. This is an excellent advantage considering the fact that for some specific types of polyolefins, a better separation might be obtained in one technique versus the other one. Thus, by having the possibility of running both CRYSTAF and TREF techniques, a more complete Chemical Composition Distribution characterization can be achieved for a given sample.

CRYSTAF-TREF is an analytical instrument intended to obtain the chemical composition distribution curve by TREF or by CRYSTAF, but it doesn’t provide any physical fraction. In TREF mode, it might be possible to collect the fractions as they elute from the column, however the instrument is not optimized for this and the process is not automated. Please refer to the PREP mc2 for an automated fractionation instrument.

In CRYSTAF mode up to 5 samples can be run in about 8 hours with no supervision required, and in TREF mode up to 5 samples can be run in about 5 hours per sample and no supervision is required.

After a CRYSTAF or a TREF run, an automated cleaning is performed by the instrument and therefore it will be ready to start another run immediately.

The standard amount used in CRYSTAF analysis is around 40mg per sample, and in TREF analysis is around 80mg.

1,2,4-Trichlorobenzene (TCB) and Orto-Dichlorobenzene (oDCB) are the most used solvents. To use other solvents please consult Polymer Char first.

No samples preparation is required by the user but weighing the dry samples and putting them inside of the vessels. The rest of the steps are performed by the instrument automatically: filling, dissolution, column loading, crystallization, elution, final cleaning, etc. Therefore, when a run is finished, another one can be started immediately.

Solvents don’t need to be handled at any time; the whole process is fully automated and the instrument is in charge of all the needed steps: filling, dissolution, column loading, crystallization, elution, final cleaning, etc. So after a CRYSTAF or a TREF run, the instrument is ready to start again immediately.

LLDPE, LDPE, HDPE, PP, E-P copolymers, multicatalyst reactor resins, and any semicrystalline polymer soluble in TCB or oDCB, giving response to C-H absorption.

CRYSTAF-TREF incorporates an infrared detector to measure the concentration. This detector is Polymer Char’s IR4 in its OEM version and therefore a composition sensor can be incorporated as well to obtain methyls or carbonyls content information.

A capillary viscometer detector can be connected to the instrument to be used in the TREF mode, to obtain information on composition-molar mass interdependence.

Thank you for your interest. If you would like to receive more information or want to request a quotation please complete this form.

This site uses cookies to give you a better browsing experience. If you continue

browsing this site we understand that you accept our use of cookies.

For more information,

please visit our Cookies Policy. You can configure which

cookies you accept by ticking the next options: